Working at height remains one of the biggest causes of fatalities and major injuries. ‘Work at height’ means work in any place where, if there were no precautions, a person could fall a distance liable to cause personal injury.

Working at heights is inherently risky, and understanding the key hazards and implementing proper safety measures is crucial to preventing accidents. Employers can take simple, practical measures to reduce the risk of their workers falling while working at height.

The usually occouring 10 key hazards while working at heights are:

- Falls from Height

- Unstable Working Surfaces

- Weather Conditions

- Improper Use of Ladders

- Falling Objects

- Inadequate Training

- Inadequate Safety Equipment

- Electrical Hazards

- Scaffolding Collapse

- Fatigue and Overexertion

Let’s delve in details these hazards and the corresponding safety measures. `

-

Falls from Height

This is the most obvious and significant risk, which can result in serious injury or death. The risk is present whenever a worker is elevated above the ground, whether on a scaffold, ladder, roof, or any other raised platform.

Safety Measures:

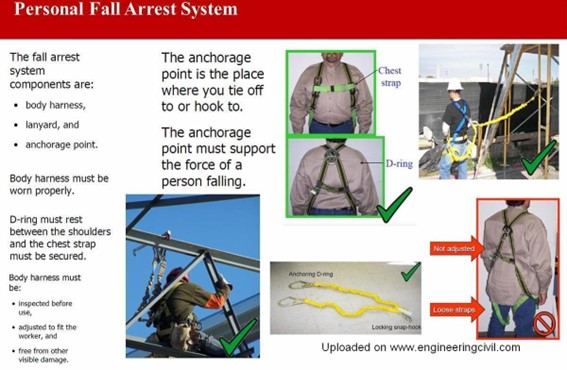

Use Of Personal Fall Arrest Systems (PFAS):

PFAS includes a body harness, anchorage point, and a connecting device like a lanyard or lifeline. It’s designed to safely stop a fall and minimize injury.

Ensure the anchorage points are capable of supporting at least 5,000 pounds per worker attached or meet the criteria of a qualified person. Regularly inspect harnesses and lanyards for wear and tear, and replace them if they show any signs of damage.

Use Of Fall Protection Equipment Like Harnesses, Guardrails, And Safety Nets:

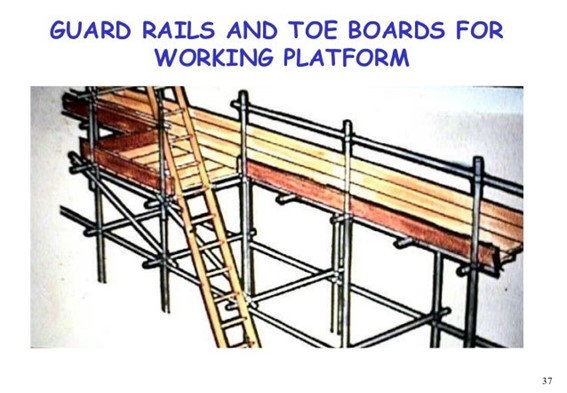

Install “guardrails” on all open sides of platforms, scaffolds, and stairs where workers are exposed to falls of 6 feet or more. Ensure guardrails are at least 42 inches high, with mid-rails and toe boards to protect from falls and falling objects.

“Safety nets” are used where scaffolds or guardrails are impractical. They should be installed as close as possible under the working surface to catch falling workers or objects. Nets should be inspected regularly for wear, damage, or deterioration.

-

Unstable Working Surfaces

Slippery, uneven, or unsecured surfaces, such as sloping roofs, loose scaffolding planks, or surfaces made slippery by water, oil, or ice, can cause workers to lose balance and fall.

Safety Measures:

Secure Platforms: Ensure all working platforms are secure, stable, and capable of supporting the load they will bear, including workers and equipment. Use scaffolding that is erected on a stable foundation, preferably on solid, level ground. If the ground is uneven, use base plates and mud sills.

Non-Slip Surfaces: Apply non-slip coatings to surfaces where slipping is a risk, such as on walkways, platforms, and ladders. In wet or icy conditions, apply sand, grit, or anti-slip materials to provide better traction.

Pre-Work Inspections: Conduct thorough inspections of all working surfaces before starting work. Look for signs of instability, such as loose boards, weak points, or slippery areas. Remove or mark any debris, clutter, or spills that could cause trips or slips.

-

Weather Conditions

Adverse weather such as rain, wind, snow, or extreme temperatures can increase the risk of accidents when working at heights. Wind can destabilize workers or materials, rain and snow can make surfaces slippery, and cold can impair manual dexterity.

Safety Measures:

Weather Monitoring: Continuously monitor weather conditions before and during work. Use reliable weather forecasting services and, if possible, weather stations on-site. Have clear guidelines in place for when work should be suspended due to adverse weather conditions, such as high winds or heavy rain.

Appropriate PPE: Use personal protective equipment suitable for the weather, such as waterproof clothing, insulated gloves, and anti-slip footwear. Ensure workers have access to shelter and heating during cold weather and are protected from excessive sun exposure in hot conditions.

Wind Shields and Barriers: Install windbreaks or barriers in areas exposed to high winds, especially on scaffolding or high platforms. Secure all tools, materials, and equipment to prevent them from being blown off platforms.

-

Improper Use of Ladders

Ladders can slip, or workers may lose their balance while climbing, leading to falls due to improper setup, use, or maintenance. Risks include the ladder slipping, tipping over, or workers losing their balance.

Safety Measures:

Proper Ladder Selection: Choose the right ladder for the job—step ladders for short tasks, extension ladders for higher work, and platform ladders for tasks that require more stability. Ensure the ladder is tall enough to reach the working height without requiring the worker to stand on the top rung.

Secure Setup: Set up ladders on stable, level surfaces. If the ground is uneven, use ladder leveling devices or leg extensions. Secure ladders at the top or bottom to prevent them from slipping. For extension ladders, ensure they are placed at the correct angle (approximately 75 degrees).

Three Points of Contact: When climbing or descending a ladder, maintain three points of contact (two hands and one foot, or two feet and one hand). Do not carry tools or materials while climbing; instead, use tool belts or hoists to lift materials. Use ladders that are appropriate for the task and ensure they are in good condition.

-

Falling Objects

Tools, equipment, or materials falling from heights can pose significant dangers to workers below, potentially causing serious injuries or fatalities. This includes tools, materials, or debris that may accidentally be knocked off or dropped.

Safety Measures:

Toe Boards and Guardrails: Install toe boards on scaffolding and guardrails to prevent tools or materials from being kicked off. Ensure that materials are stacked and stored securely, with heavier items on the bottom to prevent toppling.

Tool Lanyards and Securing Devices: Use tool lanyards to secure tools and prevent them from falling if dropped. Secure all materials and equipment on platforms, especially in windy conditions, to prevent them from being blown off.

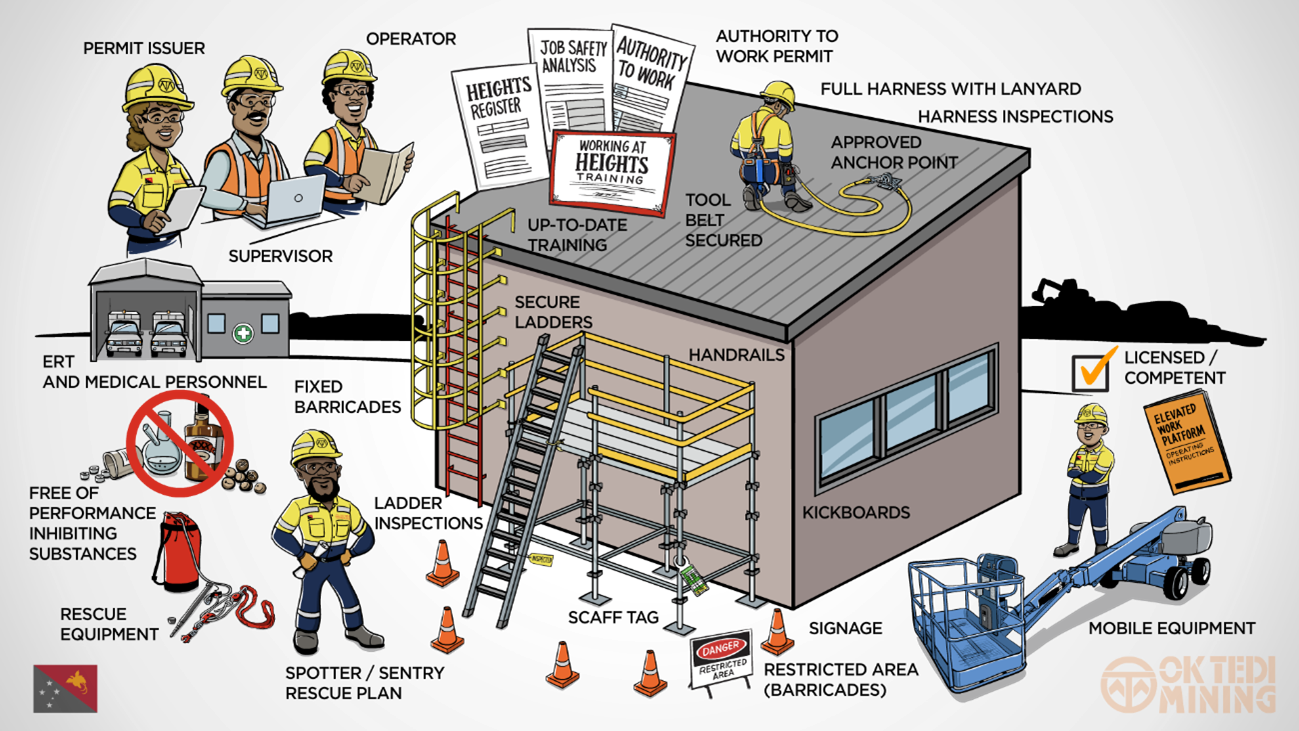

Exclusion Zones: Establish exclusion zones or barricades below areas where work is being done at height. This keeps other workers and personnel away from potential falling objects. Use warning signs and communication to ensure that workers are aware of these zones.

-

Inadequate Training

Workers who are not adequately trained may not be aware of the hazards they face or how to properly use safety equipment. This can lead to unsafe practices, increasing the risk of accidents.

Safety Measures:

Comprehensive Training Programs: Provide thorough training on the specific risks associated with working at heights, including hazard recognition, proper use of PPE, and emergency procedures. Training should cover how to correctly use, inspect, and maintain fall protection systems, ladders, and scaffolding.

Regular Training Refreshers: Conduct regular refresher training sessions to ensure workers remain up-to-date with safety procedures and standards. Training should be revisited when new equipment is introduced, or when there are changes to the working environment.

Site-Specific Training: Provide site-specific training that addresses the unique hazards of each job site. This includes specific protocols for the use of equipment and emergency evacuation procedures. Provide comprehensive training on working at heights, including hazard recognition and the proper use of fall protection equipment.

-

Inadequate Safety Equipment

Using faulty or inappropriate safety equipment can greatly increase the risk of accidents. This includes outdated, damaged, or unsuitable fall protection gear, scaffolding, or ladders.

Safety Measures:

Certified Equipment: Ensure that all safety equipment is certified by relevant authorities (e.g., OSHA, ANSI, CE) and is suitable for the intended use. Use equipment that is specifically designed for the conditions and height at which the work is being conducted.

Regular Inspection and Maintenance: Implement a routine inspection schedule for all safety equipment. Look for signs of wear, damage, or other issues that could compromise safety. Replace any equipment that shows signs of deterioration or that fails an inspection.

Proper Storage and Handling: Store safety equipment in a dry, clean environment to prevent damage from moisture, chemicals, or physical impact. Ensure that equipment is properly handled, not dropped or roughly treated, to prolong its lifespan and maintain its integrity.

-

Electrical Hazards

Working at heights near electrical lines or equipment poses a significant risk of electrocution. This is particularly dangerous when using metal ladders, scaffolding, or tools that can conduct electricity.

Safety Measures:

Safe Distances: Maintain a safe working distance from power lines and electrical equipment, as defined by regulations (often a minimum of 10 feet for overhead lines). De-energize and lockout/tagout electrical systems before working near them whenever possible.

Non-Conductive Tools and Ladders: Use ladders made of non-conductive materials (such as fiberglass) when working near electrical sources. Ensure that tools and equipment are also non-conductive or properly insulated to prevent accidental contact with live wires.

Electrical Safety Training: Provide specific training on the hazards of working near electricity, including how to recognize and avoid electrical hazards. Workers should be trained in emergency procedures in case of an electrical incident, including CPR and the use of defibrillators.

-

Scaffolding Collapse

Improperly erected or maintained scaffolding can collapse, leading to severe injuries or fatalities. Common causes include overloading, poor assembly, or inadequate bracing.

Safety Measures:

Qualified Personnel: Ensure scaffolding is erected, modified, and dismantled by trained and qualified personnel following the manufacturer’s guidelines and regulatory standards. Scaffold design and construction should be overseen by a competent person who understands the load-bearing capacity and structural integrity of the scaffolding.

Regular Inspections: Inspect scaffolding daily before use, looking for signs of wear, damage, or instability. Special attention should be given after adverse weather conditions or any incident that could affect the scaffold’s integrity. Inspections should cover the foundation, structure, connections, and guardrails, ensuring everything is secure and properly aligned.

Load Management: Do not overload scaffolding beyond its rated capacity, which includes the weight of workers, tools, and materials. Distribute the load evenly across the scaffolding platform, and avoid stacking materials in a way that could cause instability.

- Fatigue and Overexertion

Fatigue can impair a worker’s ability to concentrate, judgment, balance, coordination and react quickly, increasing the likelihood of accidents. Overexertion can lead to physical strain, increasing the risk of falls or other injuries.

Safety Measures:

Regular Breaks: Implement regular work breaks to prevent fatigue, especially during long shifts or in physically demanding tasks. Ensure that workers have access to rest areas where they can relax and hydrate during breaks.

Task Rotation: Rotate workers between different tasks to avoid prolonged periods of repetitive motion or physical strain. Assign physically demanding tasks to workers in good physical condition and ensure they have the proper training and equipment.

Monitoring and Communication: Encourage workers to communicate if they are feeling tired, stressed, or unwell. Supervisors should be vigilant for signs of fatigue in their teams. Monitor workloads and schedules to ensure workers are not being overworked or placed in situations that could lead to overexertion.

By recognizing and understanding these hazards in detail and implementing robust safety measures, organizations, employers and workers can significantly reduce the risks associated with working at heights, creating a safer working environment for everyone involved.

Join Ken Institute and unlock a world of online courses in Occupational Health and Safety, Fire Safety, Environment and Sustainability, and Mechanical Engineering. Propel your career to new heights.

In continuation to action, for exclusive HSE training, more advice or any personalized information

join us at: info@keninstitute.com

visit our website: www.keneducation.in

call +917569034271

Let’s connect on Facebook, YouTube, LinkedIn, and Instagram.