Certainly! “Plastic can be Recycled”. Recycling of Plastic is feasible but the extent to which it is recycled and the processes involved depend on various factors such as the type of plastic, local recycling facilities, effective waste management systems, consumer awareness, and advancements in recycling technologies.

It’s crucial for individuals and communities to actively participate in Recycling of Plastic programs to maximize its environmental benefits

Factors on Which Extent of Recycling Of Plastic Depends On:

- Types of Plastic

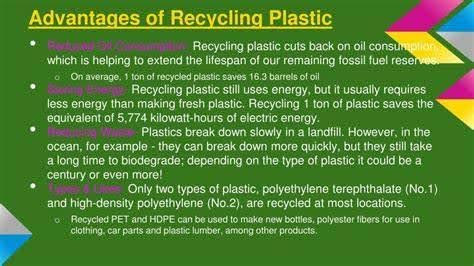

PET (Polyethylene Terephthalate): Commonly used in water and soda bottles.

Highly recyclable and often used to make polyester fibers for clothing and carpets.

HDPE (High-Density Polyethylene): Found in milk jugs, detergent bottles, and some plastic bags.

Easily recycled and used for new bottles, pipes, and plastic lumber.

PVC (Polyvinyl Chloride): Used in pipes, cable insulation, and some packaging.

Recycling is possible but challenging due to the release of harmful chlorine gas. It is less commonly recycled.

LDPE (Low-Density Polyethylene): Used in plastic bags, six-pack rings, and some containers.

Easily recycled into new plastic bags and plastic lumber.

PP (Polypropylene): Found in yogurt cups, bottle caps, and some packaging.

Easily recycled into containers, pallets, and automotive parts.

PS (Polystyrene): Used in foam packaging, disposable cups, and food service trays.

Recycled less frequently due to its lightweight nature and potential contamination issues.

Biodegradable Plastics: Some companies are developing biodegradable plastics that break down more easily in the environment. However, challenges exist in terms of scalability and ensuring they don’t contaminate traditional plastic recycling streams.

Microplastics: Microplastics are tiny plastic particles, often less than 5mm in size, which can result from the breakdown of larger plastic items. Proper recycling can mitigate the generation of microplastics, as it reduces the amount of plastic waste that enters the environment.

Water Treatment Challenges- Microplastics can be challenging to filter out in water treatment plants, potentially impacting water quality.

Nylon and Other Specialty Plastics: Some plastics, like certain types of nylon, face challenges in recycling due to their complex chemical structures.

Composite Materials: Products made from a combination of materials (e.g., packaging with mixed materials) can be difficult to recycle.

- Recycling Process

Collection: Consumers separate plastic waste from other recyclables at home or through designated collection programs.

Sorting: At recycling facilities, plastics are sorted based on their resin identification code (the number inside the recycling symbol).

Cleaning: Plastics are washed to remove any impurities, labels, or contaminants.

Shredding: The cleaned plastic is shredded into small pieces, increasing its surface area for processing.

Melting/Reforming: The shredded plastic is melted and then formed into pellets or other shapes for reuse.

Manufacturing: These pellets are used in the manufacturing of new plastic products.

Recent Developments in the field of Recycling of Plastic

- Technological Advances

Ongoing researches aim to improve the efficiency of plastic recycling processes.

Innovative technologies, show promise in breaking down plastics into their original components for higher-quality recycling.

Top Plastic Recycling Trends

- Pyrolysis

Thermal degradation of hydrocarbon plastic waste in the absence of oxygen generates Pyrolysis. Advances in pyrolysis technology, such as fast and ultra-fast pyrolysis, allow plastic waste recyclers to recycle massive amounts of waste flows within shorter periods.

- Innovative Depolymerization

Breaking down plastic waste into its monomer allows recyclers to recover a great fraction of materials from the waste source. This is due to the shorter recycling loop in depolymerization techniques.

- Advanced Mechanical Recycling

Mechanical recycling is the most profitable means to manage waste plastics. The efficiency of mechanical recycling processes significantly impacts the innovations in waste collection, sorting, and separation. This includes AI-assisted systems to speed up plastic waste classification at processing sites.

- Automated Recycling

AI-enabled solutions in the plastic recycling industry automate processing lines and improve waste separation. This enables plastic recyclers to tackle worker scarcity while enhancing operational efficiency. As a result, it reduces the workers’ exposure to high heat and increases their safety.

-

Recyclates

Most of the plastic waste ends up in landfills and incinerators because they are not designed for recycling at their end of life. That is why various startups are developing materials optimized for recycling. These include mono-material plastics that increase recycling efficiency and recyclable, low-carbon plastic alternatives.

-

Advanced Gasification

Gasification systems thermally treat plastic waste under oxygen starvation. Moreover, this technology supports a mixed waste stream that is otherwise non-recyclable.

-

Plastic Traceability

Around 91 percent of plastic products are lost due to a lack of visibility into their lifecycle. To tackle this, startups develop plastic traceability solutions that allow recyclers to track back their flow.

-

Solvent-based Purification

Dyes and additives in plastic waste limit material recovery in mechanical recycling facilities. Selective solvent dissolution or solvolysis, on the other hand, removes impurities from post-industrial and post-consumer plastic waste. This results in the recovery of very high-quality plastics.

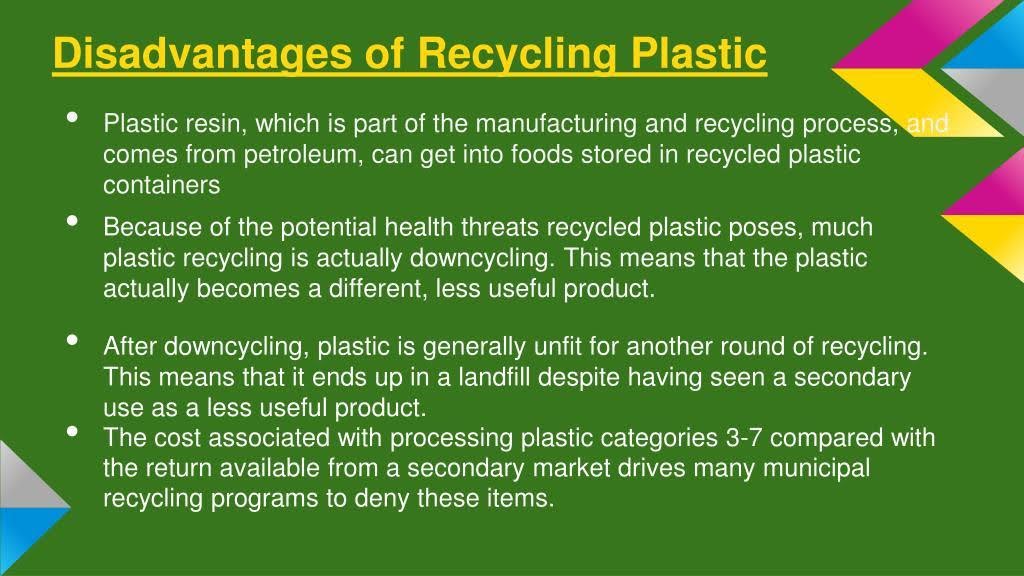

Challenges in Plastic Recycling

Contamination: While Recycling Plastic, mixing different types of plastics or non-recyclable materials can contaminate the recycling stream.

Limited Recycling of Plastic Infrastructure: Not all areas have the necessary facilities for processing all types of plastic.

Downcycling: Some plastics undergo downcycling, where the recycled product is of lower quality or utility than the original.

Consumer Awareness: Lack of awareness about proper recycling practices and the types of plastics accepted in local programs.

Environmental Impact: Recycling of plastic can reduce the demand for new raw materials, conserve energy, and decrease the amount of plastic ending up in landfills or oceans.

Single-Use Plastics: A significant challenge is posed by single-use plastics, which are often designed for convenience but can be challenging to recycle economically.

Economic Viability: The economics of recycling can be influenced by factors such as oil prices, which affect the cost comparison between using recycled and virgin plastics.

Global Recycling Rates: Variation Across Regions:

Recycling rates vary significantly globally. Some developed countries have robust recycling infrastructure, while others, particularly in the developing world, may face challenges.

Challenges in Developing Countries:

Limited Infrastructure:

Many developing countries face challenges in establishing robust recycling infrastructure, leading to increased plastic pollution.

Informal Recycling Sector:

In some regions, informal waste pickers play a crucial role in collecting and recycling plastic, but they often lack proper equipment and safety measures.

Global Plastic Waste Trade: Historically, some countries exported their plastic waste to others for recycling. However, concerns about environmental impacts and mismanagement led to restrictions on this practice.

Initiatives and Solutions

Extended Producer Responsibility (EPR):

Some regions have implemented EPR programs, where producers are responsible for the collection, recycling, or proper disposal of their products.

Plastic Bans and Restrictions:

Some areas have introduced bans or restrictions on certain single-use plastics to reduce their environmental impact and encourage alternative materials.

Public Awareness Campaigns:

Education campaigns help inform the public about proper recycling practices, reducing contamination and increasing the quality of recycled materials.

Circular Economy Approach:

The concept of a circular economy emphasizes reducing waste by designing products for reuse, recycling, or composting, thus minimizing the use of finite resources.

Plastic Pact Initiatives:

The worldwide environment caring Foundations have developed Plastic Pacts that bring together businesses, governments, and NGOs to create a circular economy for plastic.

Global Agreements:

Agreements like the Basel Convention aim to regulate the transboundary movement of hazardous waste, including certain types of plastic waste.

National Legislation:

Countries around the world are implementing and strengthening legislation to manage plastic waste effectively.

Future Outlook

Innovation in Material Design:

Scientists and engineers are working on developing new materials that are both functional and environmentally friendly, making recycling more effective.

Government Policies:

Continued efforts to establish and enforce regulations around plastic use, recycling, and waste management can have a significant impact.

Consumer Behavior Shifts:

As consumers become more environmentally conscious, there is potential for increased demand for products made from recycled materials, driving market forces to favor sustainable practices.

Collaboration and Partnerships:

Collaboration between industries, governments, and environmental organizations is essential for creating comprehensive solutions to the plastic waste problem.

Specific Aspects of Plastic Recycling

These additional points highlight the complex and multifaceted nature of plastic recycling, encompassing environmental, social, and economic considerations.

- Social and Environmental Impacts

Environmental Benefits of Recycling:

In addition to conserving resources, recycling plastic reduces greenhouse gas emissions compared to producing new plastic from raw materials.

Job Creation:

The recycling industry contributes to job creation in areas such as collection, sorting, processing, and manufacturing of recycled products.

Consumer Participation:

Proper Disposal:

Correct disposal of plastic waste by consumers is crucial for effective recycling. This involves placing plastics in designated recycling bins and following local guidelines.

Consumer Product Recycling Programs:

Some companies have initiated programs where consumers can return used products, such as beauty product containers, for recycling.

- Circular Economy

Closed-Loop Systems:

A closed-loop system involves designing products with recycling in mind, creating a continuous cycle where materials are reused to minimize waste.

Product Design Innovations:

Designers are exploring ways to make products more easily disassembled for recycling, promoting a circular economy.

Summary

Addressing these challenges requires a holistic approach involving cooperation at local, national, and international levels. Ongoing efforts in research, technology, policy, and public engagement are crucial for addressing the challenges and improving the overall effectiveness Recycling of Plastic on a global scale.

As an innovative problem-solver with ambitious goals, gain the advanced acumen and skills needed to make your career stand out, and join courses in Environment and Sustainability with the flexibility of 100% online learning.

Join Ken Institute and unlock a world of online courses in Environment and Sustainability, Occupational Health and Safety, Fire Safety, and Mechanical Engineering. Propel your career to new heights.

Get in touch with us at: info@keninstitute.com

Visit our website: www.keneducation.in

Call us on +917569034271

Let’s connect together on Facebook, YouTube, LinkedIn, and Instagram.