HSE Integrated Management System (HSE IMS)

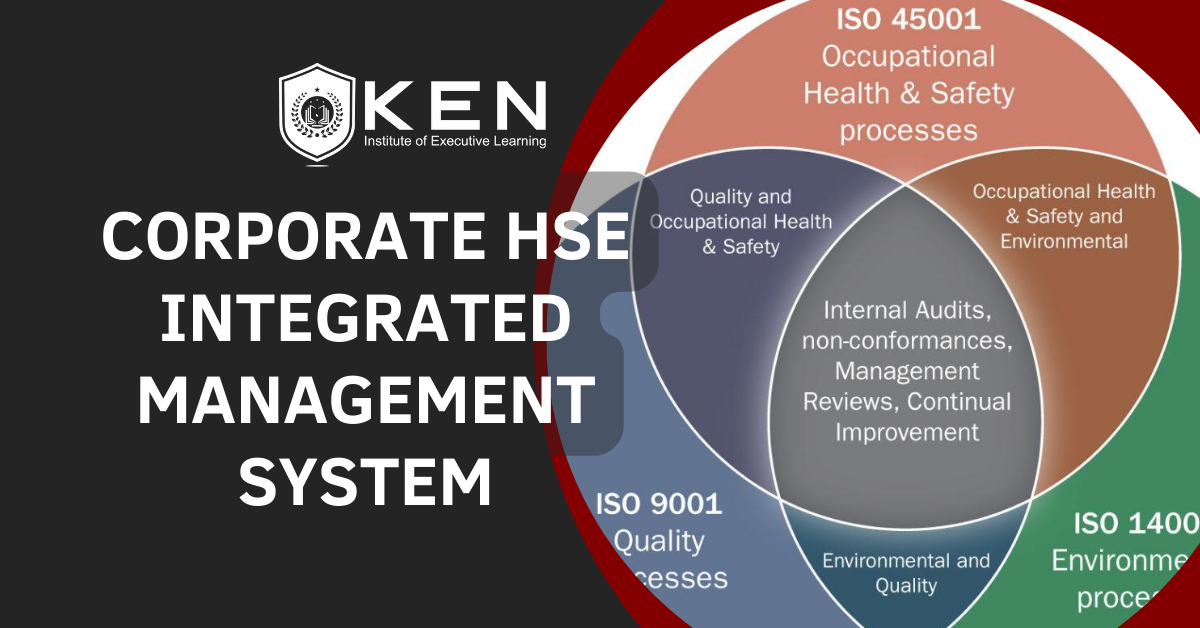

An HSE Integrated Management System has been established by the Companies to ratify their commitment to the protection of the Environment and the Health of their personnel and of all people that could be affected by the Company’s activities. And also to achieve ISO 14001:2004 and OHSAS 18001:2007 certification of its HSE IMS.

The purpose of the HSE Integrated Management System is to assess, minimize, and control all possible environmental impacts and risks for occupational health and safety under the applicable laws currently in force and the requirements of the reference regulations, with the aim of HSE performance continuous improvement.

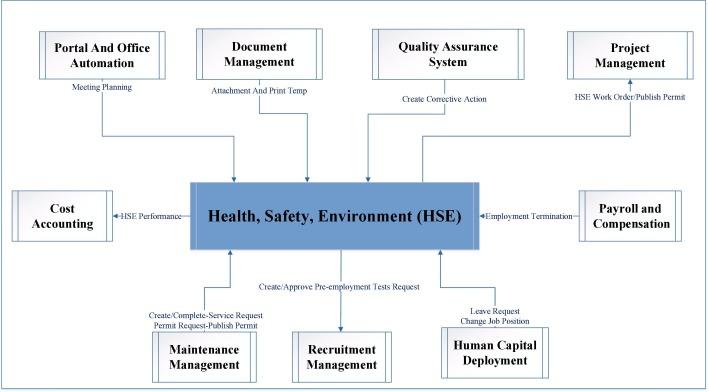

Corporate Integrated HSE Management System is used to manage:

- Industrial safety

- fire and radiation safety

- emergency prevention and response

- civil defence

- occupational and health safety

- environmental protection

An Integral Part of the Strategic Integrated HSE Management System

- The company’s Initiative is based on the requirements of the legislation and the world’s best practices.

- The domain of the Integrated HSE Management System was defined based on analysis of internal and external drivers that affect the achievement of its targets by the Company. HSE requirements apply to contractors and subcontractors, too.

- ISO Certification Based on laws and regulations, the Integrated HSE Management System was certified for compliance with ISO 14001 (Environmental Management System) and ISO 45001 (Occupational Health and Safety Management Systems) standards in 2001 for the first time.

- Health, Safety, and Environment Policy- According to the Policy, the Company has developed and introduced a package of corporate standards for the Industrial Safety, Labor, and Environmental Protection Management System

The Structure of the Integrated HSE Management System

The HSE management chain binds all the Group’s structures from the central office top down to every production facility within the Group.

Every year, the Board of Directors and Management Committee address HSE status, set tasks to improve safety performance and decide on the further development of the HSE Management System.

The Board of Directors holds annual meetings to review the status of HSE and measures to improve operational safety.

The Board members, the President, and the Management Committee receive information on emergencies and the results of investigations. Accidents and fatalities are placed on the agenda for consideration at the Board meetings.

Management Committee approves annual HSE Reports. Containing data that are essential for the Group’s strategic development and investment programs, these reports serve as an established form of analysis of HSE performance by the Company’s management.

The HSE Committee is a body to develops and submits to corporate Integrated HSE management proposals on how to approve policies, designated programs, and corporate regulations. The Committee meetings address a wide range of issues, related to the management of significant risks, environmental protection, performance against designated programs, and changes in a legal environment.

Performance Indicators- An incentive scheme, used to motivate corporate management and staff through key HSE performance indicators, is an important element of the Integrated Management System. Management Committee establishes these performance indicators for every Group’s company, and the whole Group annually.

Insurance- the Integrated Management System provides for a unified approach to voluntary third-party liability insurance and environmental insurance. All Group companies that operate hazardous production facilities carry third-party insurance. If an emergency or an accident occurs at a hazardous production facility, the Company is committed to be liable for life or health injuries and payments to compensate for damage recovery. All Group companies have enshrined employers’ liability for life and health safety in working place in-laws. Employees who suffer employment injuries, diseases or become disabled because of an occupational accident, are entitled to monetary payments in the amounts, envisaged by insurance agreements and local laws and bylaws.

Designated Programs

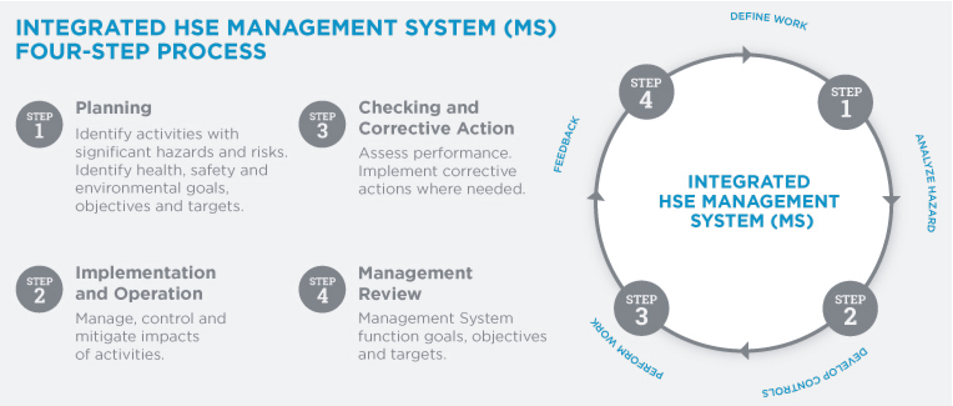

The Integrated HSE Management System provides for the identification and management of risks and environmental issues. The risk-oriented approach facilitates systemic planning, development, and implementation of annually reviewed designated programs that are paired with corporate mid-term planning procedures and approved by the Management Committee.

Committed to maintaining and enhancing its competitive advantages, the Company plans measures with a focus on an integrated and comprehensive approach to the development of the Group. Program measures, based on the best available technologies and advanced practices are meant to

- facilitate the development of assets and facilities, their technical, technological, and management potential;

- guarantee safety for employees and preserve the quality of the environment in locations where the Company’s facilities operate;

- maintain and improve the Group’s goodwill of a socially responsible business

Management System Appraisal- Appraisal of the Management System performance is based on the monitoring that incorporates audits, operation control, corporate supervision as well as safety and environmental protection contests. Control checks made as part of internal procedures help appraise how efficient the system itself and communicate of objective and up-to-date data on HSE status to the Company’s management are.

Internal and external audits provide the Company with feedback that helps consistently improve the management system for better compliance with the legislation and corporate standards.

HSE IMS Policy

The HSE IMS covers all activities, including materials and services procurement, production, maintenance, routine and non-routine activities, and personnel training.

The System is based on:

- identification of the significant environmental aspects resulting from an initial environmental analysis of all sites

- identification of ongoing hazards and assessment of related risks, to define the necessary control measures

These analyses are carried out and reviewed each time a new procedure, process, plant, work equipment, or dangerous raw material is introduced.

The main objective of the System is to manage in a controlled manner all the significant environmental aspects and the identified and assessed risks. To achieve this objective, targets and relevant programs are established in line with the policy of the organization.

Special documentation is prepared to describe the operating methods to be used to correctly manage all activities and, thus, to keep under control all occupational health and safety risks and possible significant environmental impacts in normal, exceptional, and emergency conditions.

-

Health

The protection of health is guaranteed by an integrated management system, which conforms to international OHSAS regulation 18001:2007 and is based on the specific health standard in force in the countries, as well as relevant best practices for promoting and guaranteeing the protection of the health of employees and of their families and surrounding communities as well.

Corporate HSE IMS adopts the most advanced principles, standards, and solutions and updates its procedures concerning the specific business operating needs and to the health situations, and pursues improvements in health conditions according to contents methods agreed upon also with trade union organizations.

The tools used for the application of these principles are healthcare and controls, training, and information.

-

Environment

Corporate HSE IMS is committed to limiting the environmental footprint in both its upstream and downstream activities. To this end, it adopts advanced risk assessment procedures during the entire operative cycle in order to prevent and control its impact on the territory and to protect and conserve biodiversity.

In this context, the fundamental objectives are:

- develop technologies that are increasingly safe and with a lower environmental impact;

- strength the capacity to prevent risks of soil and water contamination;

- guarantee high environmental standards in activities carried out in extreme environments;

Benefits of Corporate HSE Integrated Management Systems

-

Improving Performance

Integrated management systems will have a positive impact on specific management system components and outcomes such as improvements in quality, safety, risk, and productivity.

-

Eliminating Redundancies

One of the top benefits is being able to align the standards to find common or single management system components. These may include policies, objectives, processes, or resources.

-

Accountability

When you integrate multiple management systems at a time and establish cohesive objectives, processes, and resources, with the alignment of the systems you will see improvement in accountability.

-

Establishing Consistency

Organizations can create better consistency of the management systems, the system will become less complex. Consistency will create an improved focus on achieving a common set of objectives.

-

Reducing Bureaucracy

When multiple management standards are implemented and not integrated, dilemmas can arise by the inability to streamline decisions because of the layers of hierarchy. When the management systems are integrated, organization can take a systematic approach. The processes can better accommodate changes. When changes and decisions are easily made, this will reduce bureaucracy.

-

Cost Reduction

Integrated Management Systems allows your organization to conduct integrated audits and assessments, as well as optimize processes and resources. It can reduce the time it takes to do certain activities, and therefore reduce costs.

-

Optimize Processes and Resources

When viewing standard requirements, resources can be optimized because they become focused on process implementation and adding value rather than additional system maintenance.

-

Reducing Maintenance

When you have an integrated management system you can maintain the requirements concurrently, streamlining the process and allowing the organization to focus on improvements rather than maintaining multiple systems.

-

Integrated Audits

With an integrated management system, you can have integrated audits. They will provide your organization with lower certification costs, fewer audit interruptions, streamlined processes, a reduction in documentation, and more consistent objectives across multiple systems.

-

Facilitating Decision Making

Eliminating redundancy and creating consistency within the organization allows for a more complete view of the functional needs and performance. This integrated approach also allows the organization to analyze functional and department barriers and therefore improve communication and decision making.

To chisel out your understanding and knowledge of HSE Management,

join us atinfo@keninstitute.com or

visit our website www.keneducation.in, or

call +917569034271

Let’s connect on Facebook, YouTube, LinkedIn, and Instagram.