In modern manufacturing, the integration of CNC (Computer Numerical Control) machining, automation, and Six Sigma methodology is transforming the mechanical engineering landscape. This convergence aims to improve precision, efficiency, and quality in production while minimizing waste and defects. Integration of CNC Machining, Automation, and Six Sigma in mechanical engineering creates a highly efficient, precise, and adaptable manufacturing environment.

By integrating these technologies and methodologies, manufacturers can achieve:

- Lean Production: Minimizing waste and increasing value-added activities.

- Flexibility in Manufacturing: CNC and automation allow quick adaptation to changes in product design and volume demands.

- Quality Control: Six Sigma ensures that automated CNC processes consistently produce high-quality parts with minimal defects.

- Cost Efficiency: Reduced labor, material waste, and downtime contribute to significant cost savings.

Let’s dig deeper:

-

CNC Machining: The Backbone of Precision Manufacturing

CNC Machining refers to the use of computerized systems to control machine tools. These systems direct cutting tools, drills, and mills to shape materials with extreme precision. CNC machines are programmed using G-code, which tells the machine exactly how to move and process the workpiece.

Key advantages of CNC:

- Precision and Accuracy: CNC machines can operate with tolerances as low as a few microns. This high level of precision is crucial in industries such as aerospace, medical devices, and automotive manufacturing.

- Multi-Axis Capabilities: Modern CNC machines can have multiple axes (e.g., 3-axis, 5-axis, or even 7-axis). This allows them to produce complex geometries in a single setup, reducing the need for multiple machine setups and enhancing accuracy.

- Repeatability: CNC machines can replicate exact designs thousands of times without deviation, ensuring consistent product quality.

- Material Versatility: CNC machining works with a variety of materials, including metals (steel, aluminum, titanium), plastics, and even composites.

2. Automation: The Foundation of Modern Manufacturing Efficiency

Automation in manufacturing refers to using machines and systems to carry out production processes with minimal human intervention. It’s transforming how factories operate by increasing throughput, reducing errors, and enhancing safety. Components of Automation: Robotics, Artificial Intelligence & Machine Learning

Benefits of Automation:

- Increased Throughput: Automation speeds up production processes.

- Cost Savings: Reduced labor costs and material waste.

- Improved Safety: Dangerous tasks are handled by machines rather than humans.

- Higher Quality: Automated systems consistently produce high-quality parts.

- Six Sigma Methodologies:

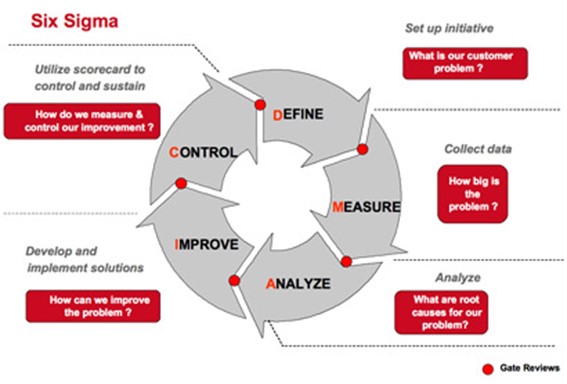

Six Sigma is a management strategy focused on improving manufacturing quality by identifying and eliminating defects and reducing variability in processes. The goal is to achieve near-perfect results by producing fewer than 3.4 defects per million opportunities.

Six Sigma Tools: Statistical Process Control (SPC), Failure Mode and Effects Analysis (FMEA), Root Cause Analysis

Benefits of Six Sigma in Manufacturing:

- Lower Defect Rates: By emphasizing continuous improvement and defect prevention, manufacturers can achieve near-perfect quality.

- Increased Efficiency: Streamlined processes reduce bottlenecks.

- Cost Reduction: Reducing defects means fewer resources are spent on reworking or scrapping faulty products.

- Customer Satisfaction: Six Sigma ensures that products meet customer expectations in terms of quality and performance by consistently meeting their expectations.

- Focus on Reducing Variability: By identifying sources of variation in the manufacturing process, companies can reduce waste and improve product quality.

The Integration: CNC Machining + Automation + Six Sigma

When CNC machining, automation, and Six Sigma are combined, they complement each other and create a high-performing, efficient, and flexible manufacturing system.

1. CNC Machining Enhanced by Automation:

- Reduced Human Intervention: Automation enables CNC machines to operate independently with minimal oversight. This reduces human error, speeds up production, and lowers labor costs.

- Automated Tool Changing: In automated CNC systems, robots can change tools without stopping production, improving machine uptime and productivity.

- Material Handling: Automated robots can load raw materials into CNC machines and remove finished products, enhancing the overall speed of the process.

2. Automation + Six Sigma for Process Control:

- Real-Time Monitoring: Automation systems with integrated sensors can monitor production variables (e.g., temperature, speed, pressure). This data feeds into Six Sigma’s Statistical Process Control (SPC) to detect deviations from ideal conditions and trigger adjustments in real time, ensuring consistent product quality.

- Predictive Maintenance: AI-powered predictive maintenance minimizes unplanned downtime by identifying issues before they cause machine breakdowns. This ensures continuous production and keeps processes within Six Sigma standards.

- Automated Quality Inspections: Robots equipped with vision systems can inspect products for defects, automatically comparing them to specifications derived from Six Sigma processes.

3. Six Sigma Applied to CNC and Automation:

- Optimizing CNC Parameters: Six Sigma tools can be used to analyze CNC machine performance and identify optimal machining parameters (such as feed rates, spindle speeds, and cutting depths) that reduce cycle time while maintaining product quality.

- Error Proofing (Poka-Yoke): In automated systems, Six Sigma principles can integrate error-proofing mechanisms to catch potential defects before they occur, ensuring flawless operations.

- Continuous Improvement: Data collected from CNC machines and automation systems is analyzed within Six Sigma frameworks to continuously improve processes, reduce cycle times, and eliminate bottlenecks.

4. Real-World Examples of Integration:

- Automotive Industry: Car manufacturers extensively use CNC machining and automation to produce engine components, body parts, and transmission systems. The precision of CNC machining is crucial for maintaining tight tolerances, while Six Sigma methodologies help maintain high-quality standards.

- Aerospace Industry: With stringent quality and safety regulations, aerospace manufacturers use CNC machining to produce highly accurate components, such as turbine blades and structural parts. Automation and Six Sigma ensure that each part meets exacting quality standards while reducing the likelihood of defects.

Future of Manufacturing

Looking ahead, The Future of Mechanical engineering Integration: the combination of CNC machining, automation, and Six Sigma will continue evolving with the rise of new technologies such as:

- Artificial Intelligence (AI): AI will play a larger role in optimizing CNC machining processes and automating quality control using advanced machine learning algorithms.

- Additive Manufacturing (3D Printing): CNC machining could be paired with 3D printing technologies for hybrid manufacturing, where parts are first printed and then machined to meet tight tolerances.

- Industry 4.0: IoT-connected machines and smart factories will enable real-time data exchange across manufacturing processes, enhancing coordination between CNC, automation, and Six Sigma methodologies.

Further integration of this trio of technologies promises to deliver more efficient, cost-effective, and high-quality manufacturing processes

along with advancements in artificial intelligence, additive manufacturing (3D printing), and smart factories. These developments will push industries toward fully automated, self-optimizing production lines, where machines communicate with each other to improve efficiency in real time.

Join Us Today To Make Your Mark on Modern Industry!

We believe in the importance of keeping abreast of the latest advancements in manufacturing. Regularly updating our knowledge helps us to stay informed about new best practices, and regulations, enabling us to deliver the most relevant content to our readers.

Join Ken Institute and unlock a world of online courses in Occupational Health and Safety, Fire Safety, Environment and Sustainability, and Mechanical Engineering.

Get in touch with us at: info@keninstitute.com

Visit our website: www.keneducation.in

Call us on +917569034271

Let’s connect on Facebook, YouTube, LinkedIn, and Instagram.