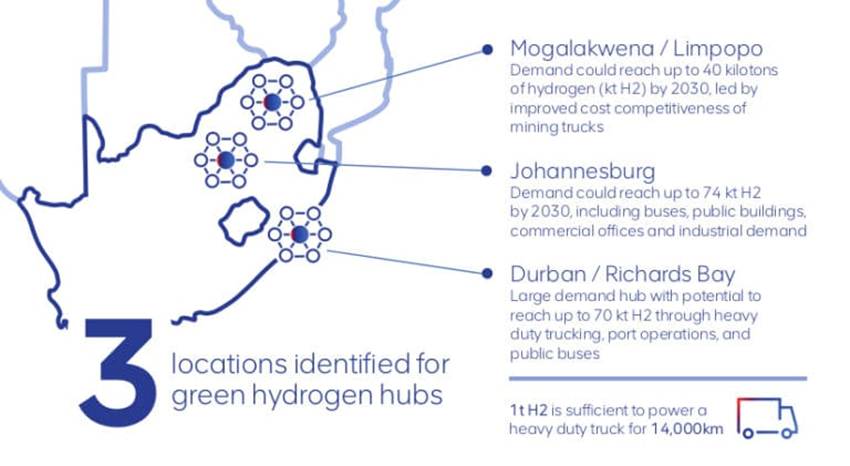

South Africa’s Hydrogen Valley project aims to create an integrated hydrogen ecosystem across three provinces- Limpopo, Gauteng, and KwaZulu-Natal linking mining, industry, and major ports to drive a green hydrogen (GH2) economy. The project is crucial for the SA’s “Just Energy Transition.”

Each project is requiring specialized infrastructure to leverage local industrial strengths and geographic advantages.

1. Mogalakwena/Limpopo Hub: The Mining Center

This hub is centered around Anglo American’s Mogalakwena PGM mine and focuses on decarbonizing heavy-duty mining operations.

Production & Power: Features a 100 MW solar PV plant to provide off-grid renewable energy for electrolysis.

Hydrogen Complex: Includes Africa’s largest electrolyzer and a dedicated zero-emission complex for production, storage, and refueling.

Mobile Infrastructure: Focuses on retrofitting heavy haulage systems, including the world’s largest hydrogen-battery hybrid mining trucks.

2. Johannesburg/Gauteng Hub: The Industrial Demand Center

This inland hub connects Johannesburg, Pretoria, and Rustenburg, focusing on heavy industry and domestic freight.

Repurposed Infrastructure: Plans to leverage South Africa’s largest existing gas distribution network for hydrogen transport and distribution.

Fueling Corridors: Establishment of refueling stations along the N3 freight corridor to support fuel cell trucks moving between the industrial heartland and the coast.

Industrial Feedstock: Integration with steel, cement, and chemical production sites (e.g., Sasolburg) to replace high-carbon feedstocks with green hydrogen.

3. Durban/Richards Bay Hub: The Export & Maritime Gateway

This coastal hub spans the ports of Durban and Richards Bay, focusing on international trade and maritime decarbonization.

Port Infrastructure: Development of low-carbon marine bunkering and hydrogen-powered port operational vehicles like forklifts.

Export Facilities: Planning for liquefaction plants and storage facilities to facilitate the export of hydrogen and green ammonia to global markets.

Refinery Repurposing: Potential conversion of closed oil refineries in Durban for low-carbon hydrogen production and processing.

Pipeline Connectivity: Utilization of existing multi-purpose pipelines connecting the coastal ports to the Johannesburg industrial hub.

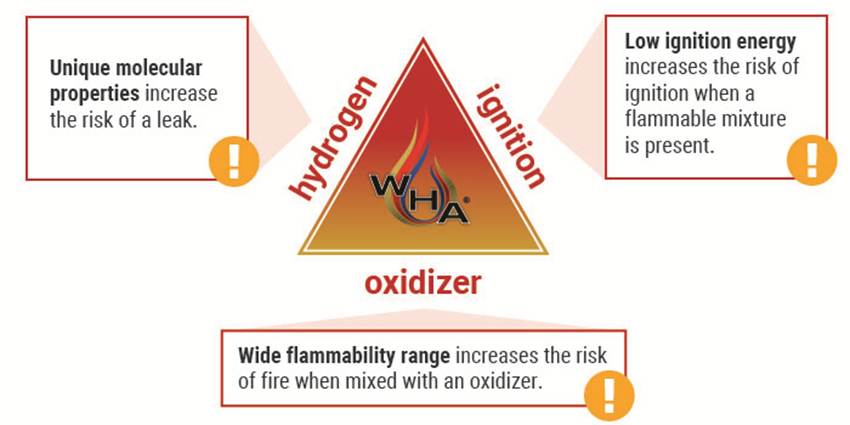

These initiatives are facing critical environmental and safety challenges centered on the unique thermophysical properties of hydrogen, which make it highly flammable, prone to causing material embrittlement, and difficult to store and transport securely.

Source of Image: hydrogencouncil

The Key Environmental and Safety Challenges in Scaling South Africa’s Green Hydrogen Economy:

1. Resource Challenges

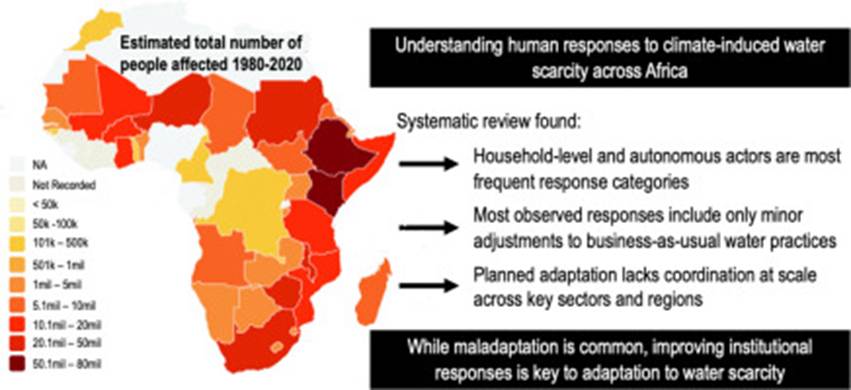

Intense Water Scarcity vs. Production Demand: The project faces severe constraints in drought-prone areas like the Northern and Western Cape, creating a conflict between local water security and industrial needs. Green hydrogen production via electrolysis requires large volumes of demineralized water.

Projects must rely on desalination, adding energy costs and complexity.

“Green Extractivism” and Land Rights: large-scale, export-oriented hydrogen projects (like Boegoebaai) lead to “green extractivism,” where local communities are displaced, and resources are exploited without local benefit.

2. Safety and Operational Risks

High Flammability and Leakage: Hydrogen is extremely flammable, has a wide range of flammability (4–75 vol%), and its small molecular size makes it prone to leaks. About 25% of hydrogen fires are caused by leaks.

Invisible Flames: Hydrogen fires are nearly invisible to the naked eye, complicating fire detection and response efforts.

Hydrogen Embrittlement: Hydrogen can cause metals (especially high-strength steels) to crack and deteriorate over time, posing significant safety hazards to storage tanks and pipelines.

Repurposing Risks: Utilizing existing gas pipelines for hydrogen, increases risks due to potential material incompatibility.

3. Scaling and Infrastructure Bottlenecks

High Costs and Economic Viability: Green hydrogen is currently up to five times more expensive to produce than fossil fuel alternatives. Without significant subsidies or carbon pricing, projects face financial viability issues, risking “stranded assets”.

Infrastructure Gaps: There is a lack of specialized infrastructure for storage, transportation, and refueling.

Grid Constraints: The South African electricity grid, especially in the Western/Northern Cape, is constrained, making it difficult to supply the necessary renewable power for electrolysis.

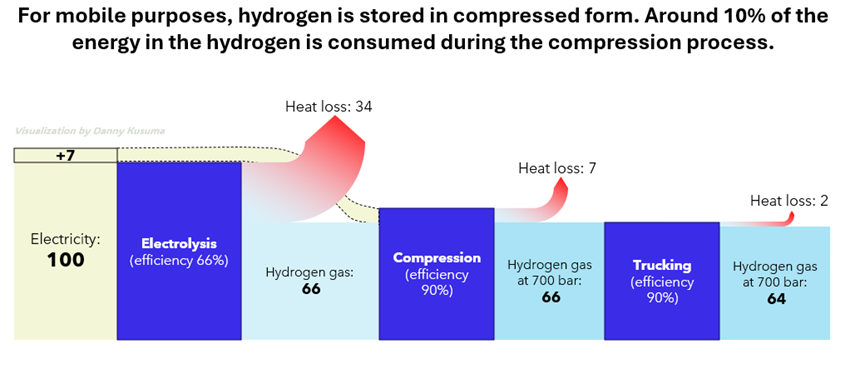

Transportation and Distribution Challenges: Hydrogen is difficult to transport, with up to 48% of energy content potentially lost through compression or conversion to carriers like ammonia. Transporting hydrogen over long distances is challenging due to its low volumetric density (3.2 times lower than natural gas). Risk of loss of containment (LOC) due to mechanical collisions (e.g., road or rail accidents) is a major concern as the industry scales.

Source of Image: dannykusuma.medium

4. Strategic and Social Challenges

Job Creation vs. Skill Deficits: The industry requires specialized skills that are currently in short supply in South Africa.

Regional Competition: South Africa faces competition from other global players, requiring rapid policy formulation and standardization of certifications.

5. Environmental Challenges

Scaling green hydrogen in South Africa introduces significant resource-related and ecological risks:

Water Scarcity and Competition: Key environmental concerns include severe water scarcity and the ecological impacts of intensified mining for critical minerals. Green hydrogen production via electrolysis requires approximately 9 kg of pure water per kg of hydrogen produced. South Africa is already a water-stressed country where demand is projected to outstrip supply as early as 2025. Large-scale projects risk worsening water insecurity for local communities and existing sectors like agriculture.

Source of Image: sciencedirect

Biodiversity and Land Usage: Large-scale renewable energy infrastructure (wind/solar farms) needed for hydrogen production negatively impact local biodiversity and ecosystems.

Desalination Impacts: To mitigate freshwater scarcity, many hubs plan to use desalinated seawater. While the cost of desalination is relatively low (roughly 4% of electrolyser costs), it is energy-intensive and can lead to coastal damage from mega-ports and brine disposal, potentially threatening marine ecosystems and fishing grounds.

Critical Mineral Extraction Risks: Approximately 84% of the world’s Platinum Group Metal (PGM) reserves essential catalysts for PEM electrolysers, lie in South Africa’s “platinum belt,” a water-scarce region. Intensified mining for these minerals poses high Environmental, Social, and Governance (ESG) risks, including acid mine drainage that decimates local water resources and causes health issues for frontline communities.

Renewable Energy Diversion: Achieving 2050 hydrogen targets could require up to 80GW of renewable capacity, eight times the current national capacity. Diverting such massive amounts of green energy for hydrogen could exacerbate existing domestic energy poverty.

6. Safety Challenges in Scaling

Hydrogen’s physical properties necessitate stringent safety protocols across the entire value chain, particularly in storage and transport:

High Flammability and Reactivity: Hydrogen has wide flammability limits (4–75% in air) and an ignition energy one order of magnitude lower than hydrocarbons. It is colourless, odourless, and tasteless, making leaks difficult to detect without specialised equipment.

Source of Image: wha-international

Material Embrittlement: Hydrogen can permeate and embrittle metals, leading to cracks, material degradation, and the eventual failure of containment systems like pipelines and storage tanks. This makes hydrogen infrastructure significantly more expensive than natural gas alternatives.

7. Storage Hazards

High-Pressure Risks: Compressed hydrogen storage carries explosion risks and requires advanced leak detection and well-ventilated systems to handle potential breaches.

Cryogenic Hazards: Storing hydrogen in liquid form at -253°C is energy-intensive and presents risks like Boil-off Gas (BOG), which must be safely vented to prevent tank ruptures.

Strategic Mitigation and Outlook:

To address these challenges, South Africa is pursuing several integrated strategies:

Hydrogen Valley Hubs: By clustering production and end-use, the project aims to minimize long-distance transport risks.

Water Innovation: Projects like the Boegoebaai hub are integrating dedicated desalination and water recycling plants directly into industrial zones to avoid competing with communal freshwater sources.

Regulatory Development: The government is exploring the use and amendment of the National Environmental Management Act to establish specific regulations for hydrogen storage and handling on land.

International Standards: South Africa is participating in global working groups to harmonise safety codes and standards for the international trade of hydrogen.

Strategic Location: Placing projects near water sources, desalination plants, or existing industrial hubs.

Phased Development: Starting with heavy-duty transport and industrial clusters where demand is already present.

Safety Standards: Implementing strict, internationally aligned safety protocols and training for the workforce.

End Lines:

The SA’s Hydrogen Valley Project promises significant decarbonisation and economic growth, as of early 2026. The success of the Hydrogen Valley Project relies on accelerating regulatory, financial, and technical solutions to convert ambitious plans into a sustainable reality.

Join us and unlock a world of online courses in Mechanical Engineering, Occupational Health and Safety, Fire Safety, and Environment and Sustainability. Propel your career to new heights.

Propel your career to new heights.

Connect now and take the next step toward professional excellence!

+91 7569034271

Let’s connect together on: Facebook, YouTube, LinkedIn, and Instagram.