Thermal systems are those that involve the storage and transfer of heat. Thermal engineering is a branch of mechanical engineering that focuses on the design, analysis, and optimization of systems and processes that involve heat transfer, such as engines, thermal power plants, refrigeration systems, and heating, ventilation, and air conditioning (HVAC) systems. Thermal systems play a crucial role in serving as the backbone for numerous processes and applications.

There are two fundamental physical elements that make up thermal systems, thermal resistances and thermal capacitance. There are also three sources of heat, a power source, a temperature source, and fluid flow.

- Thermal resistances and thermal capacitance are fundamental physical elements.

- Heat flows between objects through conduction, convection, and radiation.

Thermal Technology:

Thermal technology refers to using heat for specific purposes, such as climate control or insulation Generally, when people use the term “thermal technology,” they mean the ways we can use heat to do what we want. For instance, to climate control, for stopping the movement of heat with insulation, or changing the temperature in a room. The commercial development of the vapor-compression refrigeration cycle is a fairly recent event. The first practical system was patented by James Harrison (a Scottish-born Australian) in 1856. The subsequent adoption of refrigeration and air conditioning was a significant contributor to our current standard of living and to the growth and development. Air conditioning greatly increased worker comfort and productivity during summer months.

The importance of the Thermal systems’ technology for the development of air conditioning and refrigeration was recognized as one of the top 20 engineering achievements of the twentieth century.

The basic thermal system vapor-compression refrigeration cycle is used in a wide variety of systems and equipment. This ranges from small home refrigerators to large and complex commercial. Refrigeration installations totaling thousands of tons of cooling capacity. Numerous home appliances utilize this technology. Larger-scale applications include cold-storage warehouses, food- and beverage-processing plants of all types, ice making and transportation systems. Chemical and petrochemical processing, and natural-gas processing.

Thermal systems are at the core of mechanical engineering, influencing virtually every aspect of modern technology and infrastructure. Engineers continuously innovate and optimize these systems to address global challenges like energy efficiency, sustainability, and technological advancement. Their significance is only expected to grow as society transitions to cleaner energy and smarter technologies.

The significance of Thermal Systems:

-

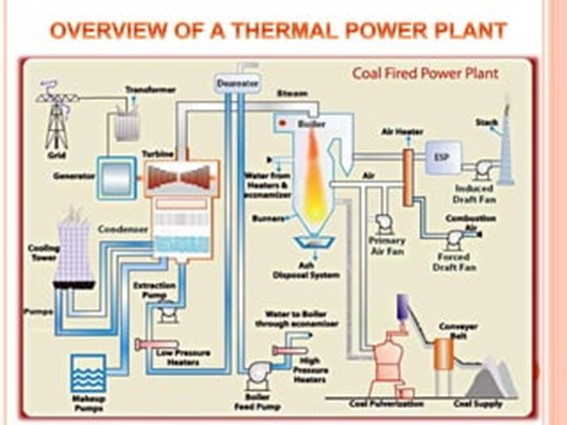

Energy Conversion and Power Generation

Thermal systems form the foundation of energy conversion technologies, ensuring the transformation of heat energy into other usable forms like mechanical or electrical energy.

Steam Turbines

- Operate on the Rankine cycle, where water is heated to produce steam that drives turbine blades.

- Used extensively in thermal power plants (coal, nuclear, and solar thermal).

- Improve cycle efficiency by employing techniques like superheating, reheating, and regenerative heating.

Gas Turbines

- Work on the Brayton cycle, using compressed air and fuel combustion to generate high-energy exhaust gases that rotate the turbine.

- Found in power plants and aviation, where high efficiency, durability, and reliability are critical.

Internal Combustion Engines

- Convert chemical energy in fuel into mechanical energy for vehicles and machinery.

- Include spark-ignition engines and compression-ignition engines.

- Thermal efficiency enhance combustion, reduce heat loss, and utilize waste heat recovery systems.

-

Heating, Ventilation, and Air Conditioning (HVAC)

HVAC systems are essential for thermal comfort and air quality in residential, commercial, and industrial buildings.

Applications and Challenges:

- Heating involves using thermal energy from combustion or electricity for space heating.

- Ventilation ensures fresh air circulation, critical for indoor air quality.

- Air conditioning employs refrigeration cycles to maintain cooling.

- Challenges include:

Energy efficiency: Developing systems that consume less energy.

Smart systems: Integration with IoT for adaptive thermal management.

Sustainable designs: Utilizing renewable energy sources like geothermal or solar heating.

-

Refrigeration and Cooling Systems

Thermal systems are crucial in preserving perishable goods, industrial processes, and maintaining electronic equipment.

Common Systems:

- Household refrigeration: Vapor-compression refrigeration cycle ensures food preservation.

- Industrial refrigeration: Includes ammonia-based systems for large-scale cooling.

- Data centers: Advanced cooling systems regulate temperature in servers, using liquid cooling or phase-change materials.

Innovations:

- Cryogenics for ultra-low temperature applications (e.g., storage of biological samples, liquefied natural gas).

- Magnetic refrigeration for more efficient and eco-friendly cooling.

-

Manufacturing and Industrial Processes

Thermal systems are integral to manufacturing processes, in industries like metallurgy, plastics, and chemicals.

Applications:

- Metalworking: Processes like annealing, quenching, and forging rely on controlled heating and cooling to modify material properties.

- Glass and ceramics: Melting and moulding require precise thermal control.

- Chemical plants: Heat exchangers and reactors manage thermal energy during chemical reactions.

Challenges:

- Achieving uniform heat distribution for product consistency.

- Managing energy consumption and heat recovery.

-

Transportation

Thermal systems are essential for the performance and efficiency of all modes of transportation, including automobiles, airplanes, and ships.

Vehicle Thermal Systems:

- Cooling systems: Prevent engines from overheating by dissipating excess heat using radiators and coolant loops.

- Turbochargers: Use exhaust heat to compress air entering the engine, boosting power output.

- Cabin systems: Include heating and air conditioning for passenger comfort.

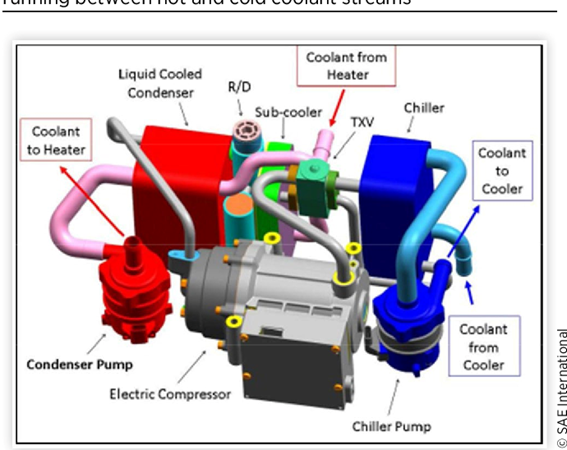

Electric and Hybrid Vehicles:

- Manage battery temperature to ensure optimal performance and lifespan.

- Use heat pumps and thermoelectric devices for heating and cooling.

-

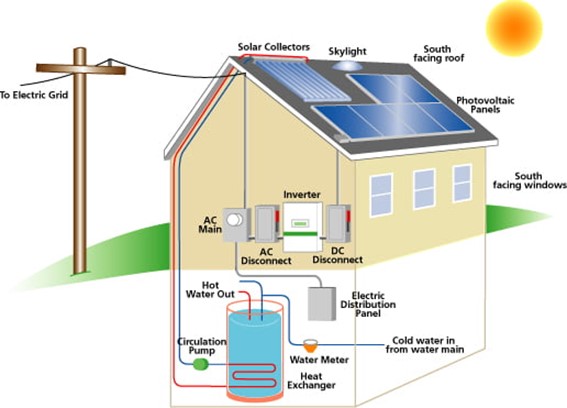

Energy Efficiency and Sustainability

Thermal systems play a pivotal role in global efforts to conserve energy and reduce greenhouse gas emissions.

Sustainable Technologies:

- Solar thermal systems: Capture and store solar energy for heating and power generation.

- Geothermal heating: Utilizes Earth’s heat for space heating and cooling.

- Waste heat recovery: Captures heat from industrial processes or engines to produce additional power.

Challenges:

- Reducing thermal losses in systems through insulation and advanced materials.

- Developing energy-efficient designs to meet stricter environmental regulations.

-

Advanced Applications

Thermal systems are critical in cutting-edge industries and technologies:

Thermal Energy Storage (TES):

- Stores excess energy for later use, especially in renewable energy systems.

- Includes sensible heat storage (molten salts) and latent heat storage (phase-change materials).

Cryogenics:

- Used in space exploration (e.g., cooling rocket propellants), medicine, and superconducting technologies.

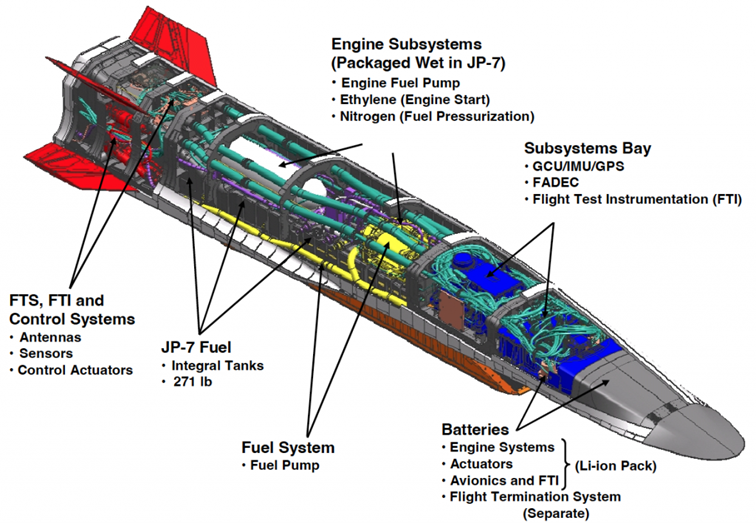

Aerospace and Defence:

- High-temperature thermal systems for jet engines and hypersonic flight.

- Thermal protection systems for spacecraft re-entry.

Electronics Cooling:

- As microprocessors and electronic devices get smaller and more powerful, thermal management becomes critical to prevent overheating and ensure reliability.

-

Design, Simulation, and Optimization

Modern engineering tools are transforming how thermal systems are designed and analyzed:

Simulation Tools:

- Computational Fluid Dynamics (CFD): Simulates heat transfer, fluid flow, and thermal interactions.

- Finite Element Analysis (FEA): Models thermal stresses and material behavior under varying temperatures.

Optimization Strategies:

- Selecting advanced materials with superior thermal conductivity or insulation.

- Integrating artificial intelligence for predictive maintenance and adaptive control of thermal systems.

-

Impact on Society

Thermal systems have a profound impact on daily life:

- Reliable power for homes and industries.

- Climate-controlled environments in extreme conditions.

- Transportation systems that connect the world.

- Preservation of food, medicine, and critical supplies.

Conclusion

Thermal systems are indispensable in mechanical engineering as they touch nearly every aspect of modern life. Whether it’s energy production, industrial manufacturing, transportation, or climate control, understanding and optimizing these systems are vital for technological advancement, sustainability, and improving quality of life.

Join Ken Institute and access various online courses of Mechanical engineering, Occupational Health and Safety, Fire Safety, and Environment and Sustainability. . we aim to educate, inform, and inspire both employees and employers about the best practices. Through education and awareness, we can make a difference.

Our programs, tailored for working professionals, offer a flexible path to advance your studies while managing your current job.

Join our global community of learners from 63 countries and lead in your industry. Boost your career and achieve professional excellence.

KEN Institute offers comprehensive programs tailored to equip you with the latest insights and up-to-date knowledge in HSE practices.

Join Ken Institute and access various online courses in, Occupational Health and Safety, Environment & Sustainability, Fire Safety and Mechanical Engineering Propel your career to new heights.

Get in touch with us at: info@keninstitute.com

Visit our website: www.keninstitute.com

Call us on +917569034271

Let’s connect together on: Facebook, YouTube, LinkedIn, and Instagram.