While working with slings, it is important to ensure your safety and the safety of those around you. Prioritizing superior sling safety when working with slings is crucial for reducing accidents and enhancing operational efficiency. Ensuring sling safety is unavoidable for preventing accidents and ensuring the longevity of equipment in lifting operations. During service, slings are subjected to conditions that affect their safe working characteristics. It is necessary therefore to ensure, as far as is reasonably practicable, that the sling is safe for continued use.

You can do several things to ensure your sling use is as safe as possible.

Here we will discuss the top 10 tips for superior sling safety. Follow these tips to stay safe while using slings!

-

Inspect Slings Regularly

Perform visual inspections of slings before each use to identify any signs of wear, tear, or damage.

What to Look For: Before each use, visually inspect the sling for any signs of damage, such as:

- For wire rope slings: Look for broken wires, severe kinks, bends, corrosion, and wire rope strand separation.

- For synthetic slings: Check for cuts, abrasions, burns, discoloration, or chemical damage.

- For chain slings: Look for stretching, wear at bearing points, cracks, gouges, or bent links.

Importance: Even small defects can lead to failure under load. Regular inspections ensure that damaged slings are removed from service before they become dangerous.

Frequency: Perform pre-use inspections daily, and schedule more thorough inspections weekly or monthly based on usage frequency.

-

Know Sling Capacities

- Ensure the sling being used is rated for the load weight. Check the manufacturer’s rated load limits, and never exceed the sling’s maximum working load limit (WLL).

Understanding Load Limits: Each type of sling has a specific rated capacity, also known as the Working Load Limit (WLL). The capacity of the sling depends on:

- Sling material (e.g., wire rope, synthetic web, chain)

- Sling configuration (e.g., vertical lift, basket hitch, or choker hitch)

- Angle of lift

Consequences of Overloading: Exceeding the WLL can result in catastrophic failure, endangering workers and equipment. Always calculate the load weight and ensure the sling’s rated capacity exceeds that weight.

Tip: Ensure the identification tags on the sling are readable, showing capacity information and proper usage guidelines.

-

Use Proper Sling Types

Select the right type of sling for the lifting job, whether a chain, wire rope, synthetic web, or round sling. The material and design of the sling should be suitable for the specific load and environment.

Different Types of Slings:

- Chain slings: Ideal for rugged or hot environments and lifting heavy, sharp, or abrasive loads.

- Wire rope slings: Versatile and commonly used for heavy loads in harsh environments but can be susceptible to kinking and bending.

- Synthetic web slings: Lightweight and flexible, excellent for delicate or finished loads but prone to cuts, chemical damage, and UV degradation.

- Round slings: Made from synthetic materials they offer flexibility, strength, and protection for delicate loads but can be easily damaged by sharp edges.

Tip: Choose the correct sling for the type of load, environmental conditions, and specific lifting application.

-

Protect Slings from Sharp Edges

When lifting objects with sharp edges, use protective padding or corner guards to prevent cutting or abrasion of the sling

material. Sharp edges can cause slings to fail prematurely.

Importance: Sharp edges, such as those on steel beams or concrete blocks, can slice through or abrade sling material, especially synthetic and wire rope slings.

Methods of Protection:

- Use edge protectors, sleeves, or wear pads made from materials like leather, plastic, or metal to act as a buffer between the sling and the load.

- Apply corner guards or padding to the load’s edges to distribute the force and reduce friction.

Tip: Ensure the protective equipment is securely placed and does not shift during lifting.

-

Avoid Twisting or Kinking Slings

Always lay slings out flat and avoid twisting, kinking, or knotting them during use. These can weaken the sling and reduce its capacity.

What Happens: Twisting or kinking, especially in wire ropes or synthetic slings, can reduce their strength by causing internal damage to fibers or strands. Knots in synthetic slings can reduce their capacity by up to 50%.

Prevention:

- Ensure the sling is laid out flat and straight before attaching to the load.

- Avoid dragging slings, especially wire ropes, to prevent twisting or rolling.

Tip: For wire rope slings, unwind any twisting before tensioning the sling.

-

Ensure Proper Sling Angle

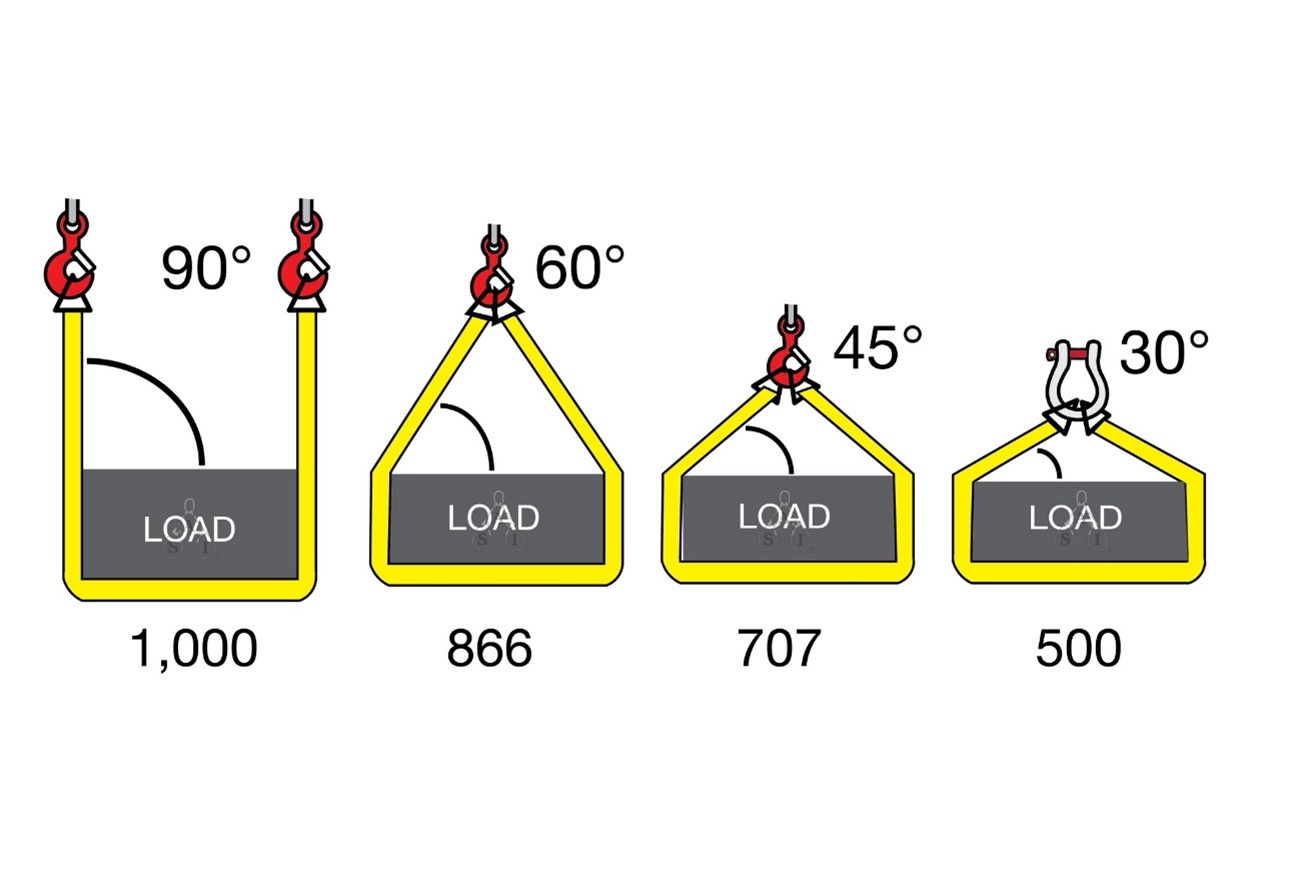

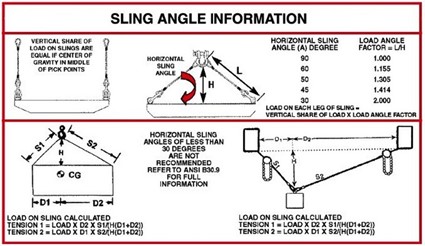

Maintain proper sling angle during lifting operations. A sling angle of less than 30 degrees can significantly increase the tension on the sling and reduce its capacity, risking sling failure.

Sling Angle and Load Stress: The angle of the sling about the load can drastically affect the force on the sling. As the sling angle decreases (becomes flatter), the tension on the sling increases:

- A 30-degree angle can double the tension on the sling compared to a 90-degree vertical lift.

- Slings with angles less than 30 degrees are considered unsafe for most lifting operations.

Best Practices:

- Keep the sling angle as close to vertical as possible.

- Use multi-leg slings (bridles) for better load distribution.

Tip: Calculate sling tension and ensure it stays within the safe load range. Use load angle charts if necessary.

-

Store Slings Correctly

Store slings in a clean, dry environment away from direct sunlight, chemicals, or extreme temperatures. Proper storage prolongs sling life by preventing exposure to damaging elements.

Proper Storage Conditions:

- Store slings in a clean, dry location away from direct sunlight, moisture, chemicals, or extreme temperatures.

- Synthetic slings can degrade if exposed to UV rays, chemicals, or extreme temperatures for extended periods.

- Wire rope slings should be protected from moisture to avoid rust and corrosion.

- Chain slings should be kept off the ground and stored in racks to prevent damage or entanglement.

Tip: Store slings in designated racks or cabinets with proper ventilation to maintain their condition and extend their lifespan.

-

Use Slings with Appropriate Hardware

Always use appropriate fittings, such as hooks, shackles, or rings, that match the sling’s capacity. Ensure that all hardware is compatible and in good working condition.

Compatible Fittings:

- Use shackles, hooks, and rings that match the capacity and type of sling being used.

- Ensure that hooks or fittings are properly seated in the sling’s eye or loop.

- Consideration of Load Dynamics: The hardware must be sized and rated for the sling and load weight. Improper fittings can create stress concentrations, leading to equipment failure.

Tip: Periodically inspect the hardware for signs of wear, corrosion, or damage.

-

Train Personnel

Ensure that all workers involved in lifting operations are properly trained in sling selection, inspection, and safe lifting practices. Well-trained personnel are key to preventing sling-related accidents.

Why Training Matters:

- Untrained or inadequately trained personnel may not recognize hazards or properly execute lifting procedures, leading to accidents.

- Workers should be familiar with how to select, inspect, and rig slings safely.

- Key Training Topics:

- Load weight calculation and sling selection.

- Proper rigging techniques for various sling configurations.

- Inspection procedures and what to do if damage is found.

Tip: Regularly conduct refresher training courses and hands-on demonstrations to reinforce safe practices.

-

Follow the Manufacturer’s Guidelines

Always refer to the manufacturer’s load rating, handling instructions, and inspection recommendations.

Guidelines and Standards:

- Follow industry standards such as OSHA and ASME (American Society of Mechanical Engineers) B30.9, which outline the proper usage, care, and inspection of slings.

- Always refer to the sling manufacturer’s guidelines and industry standards for safe use. This includes load limits, proper rigging techniques, and periodic inspection requirements.

Tip: Keep sling documentation and load charts on hand for quick reference to ensure compliance with safety standards.

- Always refer to the sling manufacturer’s guidelines and industry standards for safe use. This includes load limits, proper rigging techniques, and periodic inspection requirements.

Conclusion:

These tips form the foundation for superior sling safety in lifting operations. By prioritizing them, you can significantly reduce the risk of accidents, prevent equipment damage, and extend the service life of your slings. By adhering to these practices, workers can mitigate risks, prolong the lifespan of their equipment, and create a safer and more productive working environment.

Join Ken Institute and unlock a world of online courses in Occupational Health and Safety, Fire Safety, Environment and Sustainability, and Mechanical Engineering.

Get in touch with us at: info@keninstitute.com

Visit our website: www.keneducation.in

Call us on +917569034271

Let’s connect on Facebook, YouTube, LinkedIn, and Instagram.