Ensuring a safe environment in an automotive repair shop is crucial to protect employees, customers, and the business. Creating a safe environment requires attention to detail and adherence to strict safety protocols. By following these safety rules, you can minimize accidents, ensure compliance with safety regulations, and create a productive work environment in your automotive repair shop.

Below is a detailed guide to ensure a comprehensive safety approach:

-

Proper Use of Personal Protective Equipment (PPE)

Eye Protection:

- Wear safety goggles or glasses when handling tools, chemicals, or equipment that may create debris or splashes.

- Safety goggles or glasses should have side shields and be impact-resistant.

- Use a face shield for tasks like grinding or welding to protect against flying debris and sparks.

Hand Protection:

- Use gloves when handling chemicals, hot components, or sharp tools.

- Use nitrile gloves for handling chemicals and heat-resistant gloves when dealing with hot parts.

- Ensure gloves fit snugly and are suitable for the task (e.g., no loose gloves around rotating machinery).

Hearing Protection:

- Wear earplugs or earmuffs in noisy environments.

- Prolonged exposure to noise above 85 decibels can cause hearing damage.

Respiratory Protection:

- Use masks or respirators when working with paint, dust, or fumes. Ensure proper filtration levels for the type of exposure.

Footwear: Use non-slip, steel-toe boots to protect against falling objects and slippery floors.

- Non-slip soles and steel-toe boots prevent injuries from falling objects and slippery surfaces.

2. Maintain a Clean and Organized Workspace

Tool Storage:

- Keep tools and equipment stored properly to prevent tripping or falling hazards.

- Use pegboards, tool chests, and labeled storage to keep tools organized.

Waste Management:

- Regularly empty trash bins, especially those containing flammable materials like rags soaked in oil or solvents.

- Dispose of waste materials (e.g., rags, filters, fluids) in designated receptacles.

- Provide separate containers for recyclable materials such as metal and plastics.

Spill Control:

- Regularly clean up spills, oils, or grease to prevent slips.

- Use absorbent materials like spill mats or kitty litter to clean up oil or chemical spills immediately.

- Equip the shop with spill kits and ensure all employees know how to use them.

-

Safe Equipment Use

Inspections:

- Regularly check for frayed cords, worn-out tool parts, or malfunctioning machines.

- Inspect tools and machinery regularly for wear or damage before use.

Training:

- Train employees on proper usage and safety features of all tools and machinery.

Lockout/Tagout (LOTO):

- Implement LOTO procedures to ensure equipment is not accidentally powered on during maintenance.

- Replace or repair damaged items immediately.

- Use equipment according to the manufacturer’s instructions.

Lifting Equipment:

- Only certified employees should operate vehicle lifts. Inspect lifts for hydraulic leaks and ensure safety locks are functional.

- Ensure power tools have functional safety guards.

- Always disconnect equipment from power sources when performing maintenance or adjustments.

-

Proper Handling and Storage of Chemicals

Storage:

- Store chemicals in fireproof, ventilated cabinets.

- Label all containers clearly.

- Separate incompatible materials (e.g., acids from bases or flammables from oxidizers).

- Store chemicals like oil, antifreeze, and solvents in approved, clearly labeled containers.

Material Safety Data Sheets (MSDS):

- Maintain MSDS for all hazardous substances and ensure they are easily accessible.

Ventilation:

- Use exhaust fans or ventilation hoods to reduce the buildup of fumes in enclosed areas.

- Ensure proper ventilation when working with fumes or vapors.

Handling:

- Always pour chemicals slowly to avoid splashes. Wear chemical-resistant gloves and aprons.

- Follow proper disposal procedures for hazardous waste.

-

Fire Safety Measures

Fire Extinguishers:

- Place extinguishers throughout the shop, ensuring they are rated for Class B (flammable liquids) and Class C (electrical fires).

- Keep fire extinguishers accessible, well-maintained, and appropriate for potential fire types (e.g., grease, electrical).

- Conduct monthly checks to ensure extinguishers are charged and accessible.

No Smoking Policy:

- Enforce a strict no-smoking rule near flammable substances and in work areas.

Fire Exits:

- Keep exits unobstructed and clearly marked.

- Train employees on emergency evacuation procedures.

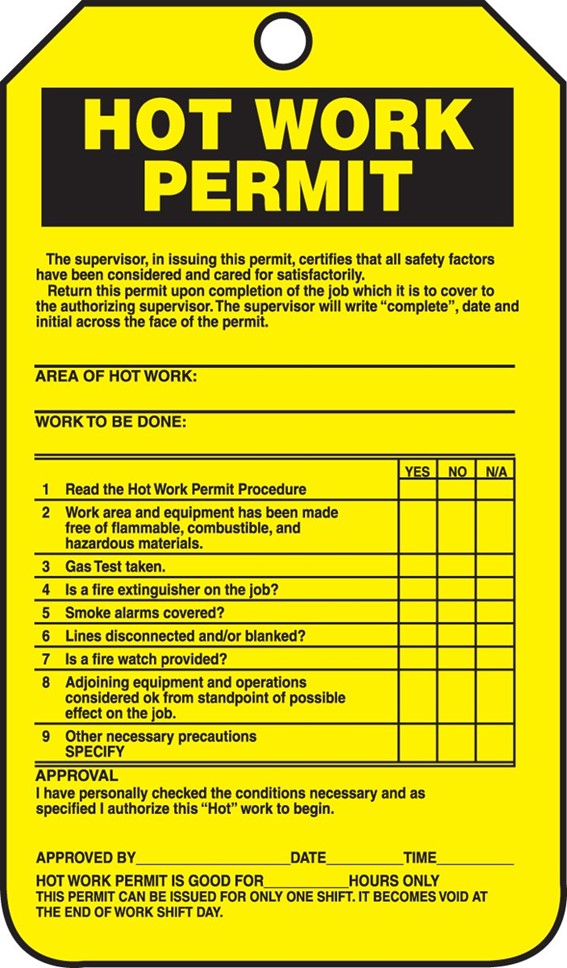

Hot Work Permits:

- For welding, cutting, or soldering, implement a permit system to ensure fire watch protocols are in place.

- Avoid open flames near flammable substances.

-

Lifting and Moving Heavy Objects

Safe Lifting Techniques:

- Use proper techniques. Keep the back straight and lift with the legs.

- Avoid twisting the body while carrying heavy objects.

Hoists and Jacks:

- Utilize hoists, jacks, or lifting equipment to handle heavy vehicle parts.

- Inspect for wear and tear.

- Ensure the jack stands are rated for the vehicle’s weight and positioned correctly.

- Never exceed the weight limits of lifting equipment.

- Never work under a vehicle without ensuring it is properly supported by jack stands.

-

Electrical Safety

Battery Handling:

- Disconnect the negative terminal first to prevent short circuits.

- Use insulated tools when working near batteries.

Hybrid and Electric Vehicles:

- Be cautious of high-voltage systems in electric or hybrid vehicles.

- Disconnect batteries before working on a vehicle’s electrical system.

- Deactivate high-voltage systems before repairs.

- Wear rubber gloves rated for electrical work.

Cables and Wires:

- Avoid running extension cords through walkways. Replace frayed or damaged cords immediately.

- Avoid using damaged extension cords or electrical tools.

8. Training and Communication

Regular Safety Meetings:

- Hold toolbox talks to address common hazards and discuss improvements.

- Communicate safety protocols clearly and update them as needed.

Incident Reporting:

- Encourage employees to report accidents or near misses to identify areas for improvement.

Clear Signage:

- Post warning signs around high-risk areas, such as flammable storage or equipment zones.

-

Emergency Preparedness

First Aid Training:

- Train staff on basic first aid, CPR, and how to use emergency eyewash stations.

Evacuation Drills:

- Conduct periodic fire and emergency evacuation drills. Assign roles like fire marshals or first responders.

- Ensure all employees know emergency contacts and procedures.

Emergency Kits:

- Keep first-aid kits well-stocked and accessible.

- Stock kits with bandages, splints, burn creams, and emergency contact information.

-

Follow Legal and Industry Standards / Compliance

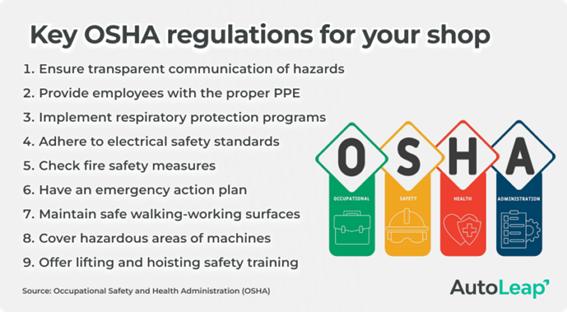

OSHA Compliance:

- Adhere to Occupational Safety and Health Administration (OSHA) regulations or equivalent safety standards in your region.

- Follow standards for hazard communication, lockout/tagout, and personal protective equipment.

- Display necessary safety signs and warnings throughout the shop.

Environmental Regulations:

- Comply with local laws on waste disposal, emissions, and chemical handling.

Safety Inspections:

- Perform regular audits to ensure all safety measures are up to date and effective.

Advanced Practices

By integrating these advanced practices, automotive repair shops can build a robust safety culture.

- Fit Testing for Respirators: Conduct annual fit tests for respirators to ensure they provide an effective seal against the face.

- Customized PPE for Specific Roles: Mechanics working with electrical systems may need dielectric gloves to protect against electrical shocks.

- 5S Methodology (Sort, Set in order, Shine, Standardize, Sustain): A lean management tool that systematically organizes the workspace to improve efficiency and safety.

- Anti-Fatigue Mats: Use mats in areas where employees stand for long periods to reduce fatigue and lower the risk of slips.

- Zone Marking: Clearly mark walkways, hazardous areas, and tool zones using reflective tape or paint.

- Digital Inventory Systems: Implement barcoding or RFID tags for tool and equipment management to reduce misplaced tools and improve efficiency.

- Drainage Systems: Ensure floors have adequate drainage to manage spills effectively.

- Air Compressors: Ensure proper PSI settings for different tools. Inspect hoses for leaks and secure them with quick-release couplings.

- Vehicle Lifts: Use locking mechanisms during inspections. Follow manufacturer-recommended maintenance schedules for lift components.

- Shock Isolation Platforms: For heavy machinery, these reduce vibrations that may cause instability.

- Telemetry Systems: Equip advanced tools with telemetry to monitor performance and detect malfunctions before they occur.

- Flammable Liquids: Store in explosion-proof cabinets. Limit the amount stored outside of cabinets to a single day’s supply.

- Battery Acid Handling: Use neutralizing agents like baking soda for spills. Equip stations with acid-resistant containment trays.

- Chemical Segregation Charts: Post visual charts to clearly indicate which substances should not be stored together (e.g., oxidizers with flammables).

- Automated Ventilation Systems: Install sensors that activate fans when airborne chemical concentrations rise above safe levels.

- Static Grounding Systems: Use grounding straps or clamps for flammable liquid containers to prevent static electricity buildup.

- Thermal Imaging Cameras: Use these to inspect equipment for overheating parts that could ignite.

- Fire Suppression Systems: Install overhead sprinkler systems or specialized suppression systems for areas with heavy machinery.

- Adjustable Workbenches: Reduce strain by allowing mechanics to work at comfortable heights.

- Lift Assist Devices: Use powered devices like hydraulic lifts or hoists for engine blocks or other heavy components.

- Exoskeleton Technology: Equip employees with wearable robotic systems for enhanced lifting support.

- Dynamic Balancing Equipment: Use tools that automatically adjust weight distribution when moving irregularly shaped parts.

- Static Discharge Prevention: Use anti-static mats and grounding straps when working on electrical systems.

- Thermal Imaging Inspections: Regularly scan electrical systems for hotspots indicating potential faults.

By implementing these detailed measures, automotive repair shops can significantly reduce risks, enhance productivity, and maintain a safe and compliant work environment.

Join Ken Institute and unlock a world of online courses in Occupational Health and Safety, Fire Safety, Environment and Sustainability, and Mechanical Engineering.

Get in touch with us at: info@keninstitute.com

Visit our website: www.keninstitute.com

Call us on +917569034271

Let’s connect together on: Facebook, YouTube, LinkedIn, and Instagram.