Designing for desert conditions in the Gulf region (such as the UAE, Kuwait, and Saudi Arabia) poses significant Mechanical Engineering Challenges due to extreme heat, high solar radiation, sandstorms, and problematic soil properties. Mechanical engineers and architects must adopt specialized strategies for resilient structures and energy efficiency in these harsh environments.

These solutions integrate mechanical, structural, and architectural engineering for enduring, sustainable developments in Gulf desert cities.

Mechanical Engineering Challenges in the Gulf Desert

Extreme Temperatures: Summer temperatures often exceed 50°C, affecting the thermal expansion and fatigue of building and machine materials, requiring enhanced cooling systems and robust thermal insulation.

High Solar Radiation: Mechanical systems and building envelopes must limit heat gain; advanced glass, reflective surfaces, and strategic shading are critical for reducing cooling loads.

Frequent Sandstorms: The most complicated challenge for mechanical engineers is to compromise machinery, HVAC units, and building systems. Engineers use filters, air-sealing, and specialized coatings to minimize abrasion and maintain equipment performance.

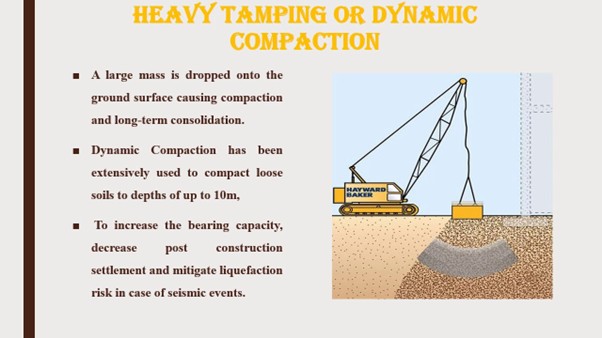

Soil Stability: Loose desert soils require advanced foundation techniques like dynamic soil compaction or deep pile foundations to prevent settlement and ensure load-bearing capacity.

Energy Demands: Reliance on cooling creates major energy demands. Passive design techniques such as insulation, strategic orientation, shading devices, thermal mass walls, and natural ventilation play a major role in making systems more efficient.

Mechanical Engineering Solutions and Innovations

Dynamic Soil Compaction: As seen in Kuwait’s “Sea City” project, engineers use dynamic compaction, dropping heavy weights with duty-cycle cranes to densify sandy ground, reducing liquefaction risk and providing a stable base for construction.

Climate-Responsive Architecture: Adaptive systems include high-albedo materials, insulated walls, triple-glazed windows, and smart facades that block solar heat while maximizing daylight.

Wind and Sand Mitigation: Landscape design, fencing, and green barriers around buildings reduce sand movement and abrasion, minimizing the impact of sandstorms on buildings and mechanical components.

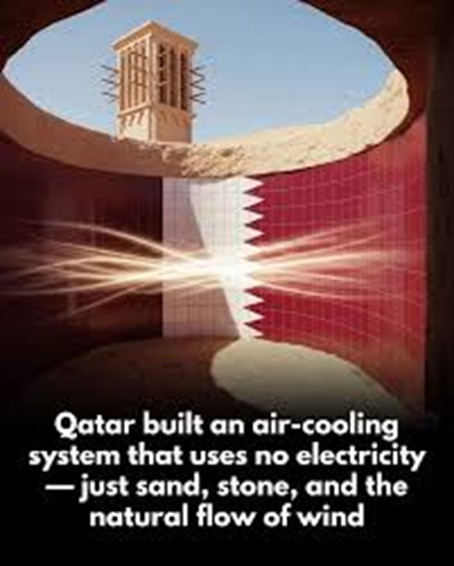

Traditional and Modern Synergy: Blending ancient methods (e.g., thick walls, small windows, internal courtyards) with modern innovations (high-performance materials, automated climate controls) increases resilience and comfort in desert environments.

The Biggest HVAC Challenges in Gulf Desert Building

Extreme Heat: Temperatures often exceed 40-50°C, overloading compressors and increasing wear and tear on HVAC systems. Systems must have powerful cooling mechanisms yet operate efficiently despite extreme conditions.

Dust and Sand: Desert air contains high levels of dust and sand that clog filters, coat internal components, and reduce air quality and system efficiency. Advanced filtration, protective measures, and rigorous maintenance are critical to keep HVAC systems running effectively.

Energy Efficiency: Cooling in desert climates consumes substantial energy. Building design elements like insulation, shading, and window glazing reduce HVAC loads. Additionally, technologies such as variable refrigerant flow systems, smart thermostats, and energy recovery systems contribute to lowering energy consumption.

Indoor Air Quality and Ventilation: Keeping fresh air circulating while retaining cooled air is a challenge due to the need for sealed buildings. Balanced ventilation systems including energy recovery ventilators (ERVs) and zoned cooling systems help maintain air quality without excessive energy waste.

Continuous Usage: HVAC systems run year-round, increasing wear and maintenance demands. Systems must be designed for durability and reliability under constant use conditions.

Key Solutions

These challenges require HVAC systems specifically engineered for desert conditions, balancing strong cooling capacity, energy efficiency, durability, and high indoor air quality to provide comfort in Gulf region buildings.

Use of High-Efficiency Filtration and Sealing Techniques: to combat dust infiltration.

Integration of smart building controls: for optimized temperature and ventilation management.

Use of Advanced Cooling Technologies: like thermal ice-storage systems to reduce peak energy loads (e.g., Burj Khalifa).

Designing Buildings with Well-Insulated Envelopes: to minimize HVAC workload.

Prevent Sand Ingress in Mechanical Equipment

Sand can cause abrasion, blockages, erosion, and eventual equipment failure if not managed effectively.

Effective Methods to Prevent Sand Ingress

Use of Filters and Screens: Installing specialized sand screens, mesh, or filters (including slotted liners, wire-wrapped screens, pre-packed, or sintered pack screens) in areas exposed to sand helps trap particles before they enter sensitive mechanical systems.

Protective Barriers and Guards: Devices like sand guards act as barriers, stopping sand particles from entering and damaging the system, thereby preventing erosion and blockages.

Sealed System Design: Designing enclosures and machinery with tightly sealed joints minimizes entry points for sand. Using high-quality gaskets and seals at all potential ingress sites is vital, especially in electrical, control, and rotating equipment exposed to desert conditions.

Material Selection: Using abrasion-resistant materials (such as certain grades of stainless steel or rubberized parts) enhances durability when exposed to sand-laden environments.

Image Source: sciencedirect

Regular Maintenance: Frequent inspection and cleaning of filters, screens, vents, and exposed components prevent sand accumulation and ensure system reliability.

Surface Facility Features: In large installations, deploying erosion-resistant chokes, impact tees, sand jet devices, and profile instrumentation in separators helps manage and remove sand at various processing stages.

These mechanical and design approaches help to keep sand out of critical mechanical equipment, ensuring long-term operation and reducing the risk of costly failures in sandy environments.

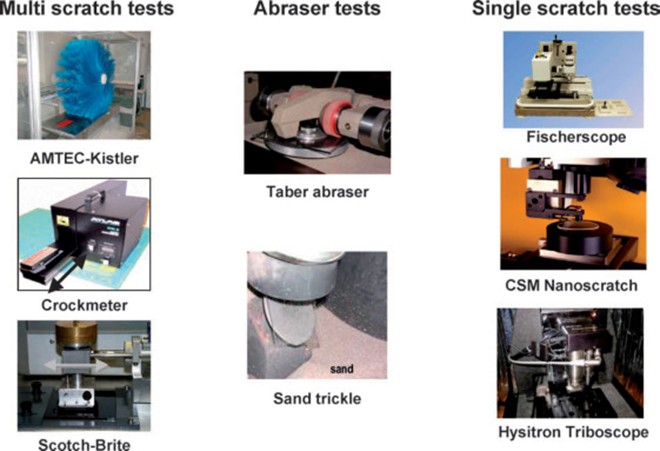

Materials and Coatings to Reduce Sand Erosion On Parts

Selecting the proper combination of base materials and erosion-resistant coatings provides lasting protection for mechanical parts exposed to harsh, sandy environments.

Suitable Materials for Sand Erosion Resistance

Carbide Alloys and Hardened Steels: Materials such as tungsten carbide and hardened alloy steels (including white irons and work-hardening manganese steel) are widely used for their high abrasion resistance in components exposed to sand.

Ceramics: Alumina, zirconia, and silicon nitride ceramics exhibit exceptional abrasion resistance due to their hardness, though they have lower impact toughness.

Abrasion-Resistant Polymers: Polyurethane coatings and linings are effective and increasingly used where flexibility and impact resistance are needed, such as in rotor blades and various composite surfaces.

Thermoplastic Composites: Filled PTFE and PTFE/PEEK blends provide abrasion resistance in pump systems and can operate at a broad temperature range.

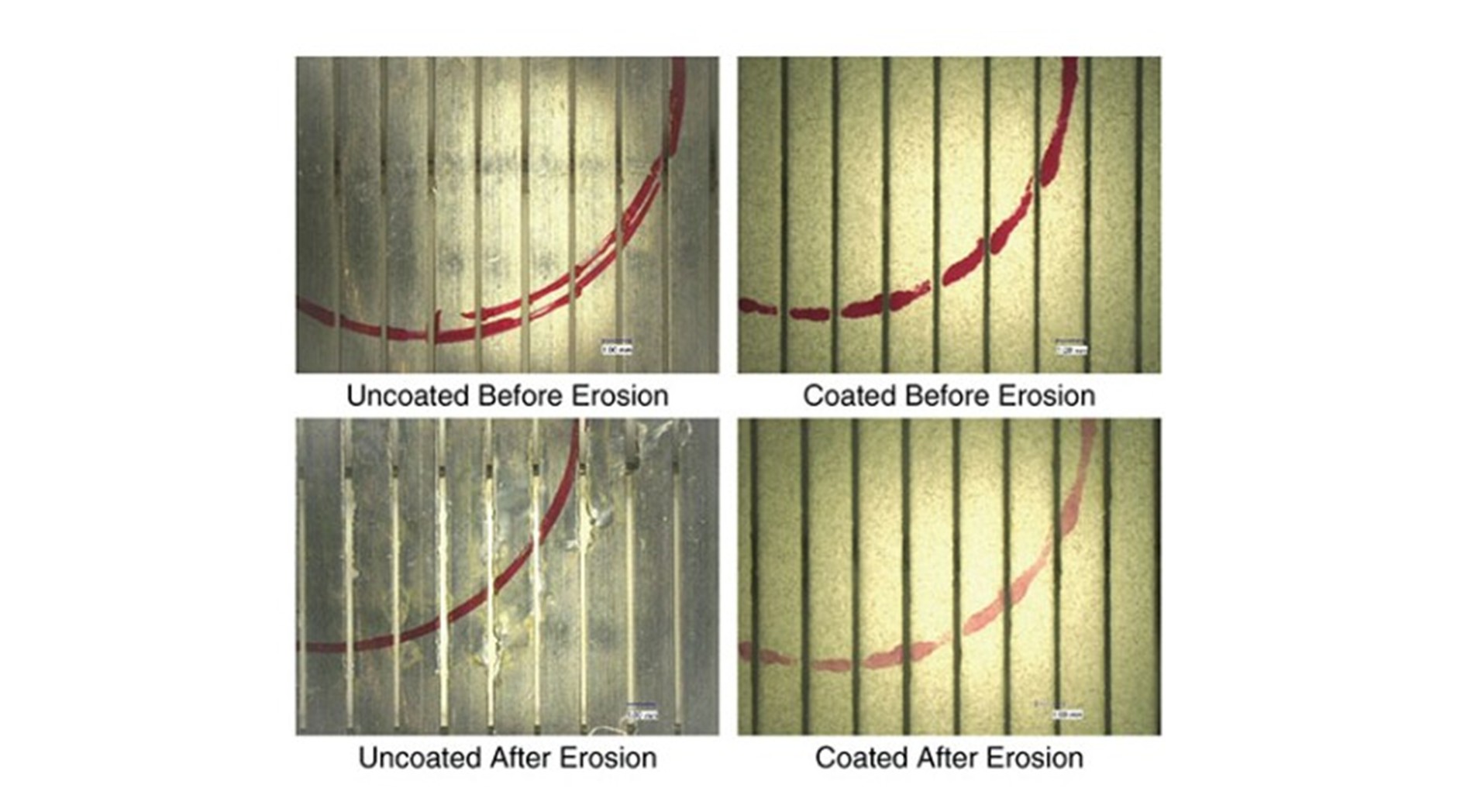

Image Source: corrosionpedia

Notable Erosion-Resistant Coatings

Tungsten Carbide and Metal-Matrix Coatings: Chemical vapor deposited coatings like Hardide-T (tungsten carbide-based) provide highly durable, pore-free protection against sand erosion and corrosion, dramatically reducing erosion rates compared to stainless steel and other hard coatings.

Polymer Alloy Coatings: New generations of polymer alloy thin-film coatings, such as those developed by Belzona offer strong adhesion and resistance to erosion-corrosion for surfaces exposed to sand-laden flows.

Ceramic and Cermet Coatings: Ceramic-based coatings (e.g., ZrAlSiN, ZrN) enhance the toughness and erosion resistance and are applied to critical surfaces using thermal spray or similar techniques.

Polyurethane Linings: Tested to protect composite and metal surfaces, especially in high-impact or flexing applications.

Image Source: jpt.spe

The Best Installation Practices to Extend Coated Parts

Proper installation helps maintain the performance of erosion-resistant coatings and prevent premature failure.

Surface Preparation: Before applying any coating, ensure surfaces are thoroughly cleaned and roughened as needed (using blasting or chemical treatments) to maximize coating adhesion and prevent peeling or under film corrosion.

Precise Application: Use correct application techniques (spray, brush, dip, or thermal spray) ensuring consistent thickness according to manufacturer specifications. Control factors like curing time, temperature, and humidity for optimal bonding.

Protect Edges and Joints: Pay special attention to seams, edges, and moving joints by either reinforcing with thicker coatings or using flexible sealants to prevent early failure in high-wear areas.

Avoid Mechanical Damage: During installation, handle coated parts carefully to prevent scratches, dents, or other damage that could create entry points for sand and moisture.

Inspection and Maintenance Strategies

Routine Visual Inspections: Regularly check for signs of coating wear, blistering, peeling, or impact damage—especially after sandstorms or exposure to high-abrasion incidents.

Thickness Gauging: Use ultrasonic or magnetic gauges to measure coating thickness and ensure it remains within serviceable limits, as thinning indicates loss of protective capability.

Adhesion Testing: Periodically test adhesion strength at critical points using methods like cross-hatch or pull-off tests, identifying weak spots before failure occurs.

Timely Recoating: Address minor damage with spot repairs and plan timely recoating cycles for high-wear zones, ideally before exposed substrate corrosion or severe erosion can develop.

Documentation: Maintain detailed records of installation date, inspection findings, repairs, and reapplication to track performance and anticipate service needs.

Careful installation and diligent inspection help maximize the effectiveness and service life of protective coatings in environments affected by sand erosion and abrasion.

Summary

The hot desert region is facing destructive environmental impacts, such as global warming, climate change and pollution which is then used to

enhance the indoor environment of buildings. These challenges have encouraged designers and engineers to adopt passive design strategies

to reduce the negative environmental impacts. These design strategies have increasingly effective and attracted the attention of researchers around the world.

Join Us!

Join us and unlock a world of online courses in Mechanical Engineering, Occupational Health and Safety, Fire Safety, and Environment and Sustainability. Propel your career to new heights.

Propel your career to new heights.

Connect now and take the next step toward professional excellence!

+91 7569034271

Let’s connect together on: Facebook, YouTube, LinkedIn, and Instagram.