Composite materials have become indispensable in various engineering applications due to their superior mechanical properties and design flexibility. The mechanical behavior of composite materials plays a pivotal role in their adoption across engineering fields. Because of their mechanical properties, types, influencing factors, testing methods, and real-world applications, these materials outperform traditional materials in strength-to-weight ratio, durability, and adaptability, making them ideal for sectors such as aerospace, automotive, civil engineering, and sports equipment.

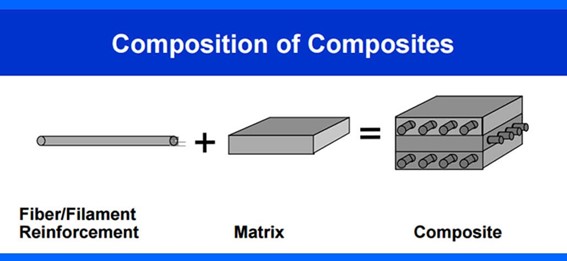

Composite materials, composed of two or more constituent materials with significantly different physical or chemical properties, have transformed engineering design and functionality. These constituents remain separate and distinct at the macroscopic level within the finished structure. Their ability to provide enhanced mechanical performance, such as increased strength, stiffness, and resistance to fatigue, makes them highly valuable in modern mechanical engineering practices.

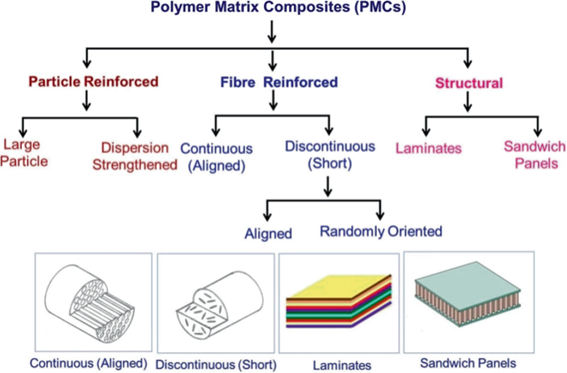

Types of Composite Materials, these are broadly classified into the following categories:

-

Polymer Matrix Composites (PMCs):

These consist of a polymer resin matrix reinforced with fibers like carbon or glass. PMCs are widely used in aerospace and automotive industries. They are lightweight, corrosion-resistant, and relatively easy to process.

-

Metal Matrix Composites (MMCs):

These include a metallic matrix such as aluminum reinforced with ceramic fibers or particles, offering improved strength, stiffness, and thermal stability. MMCs are used in high-performance engine components and thermal management systems.

-

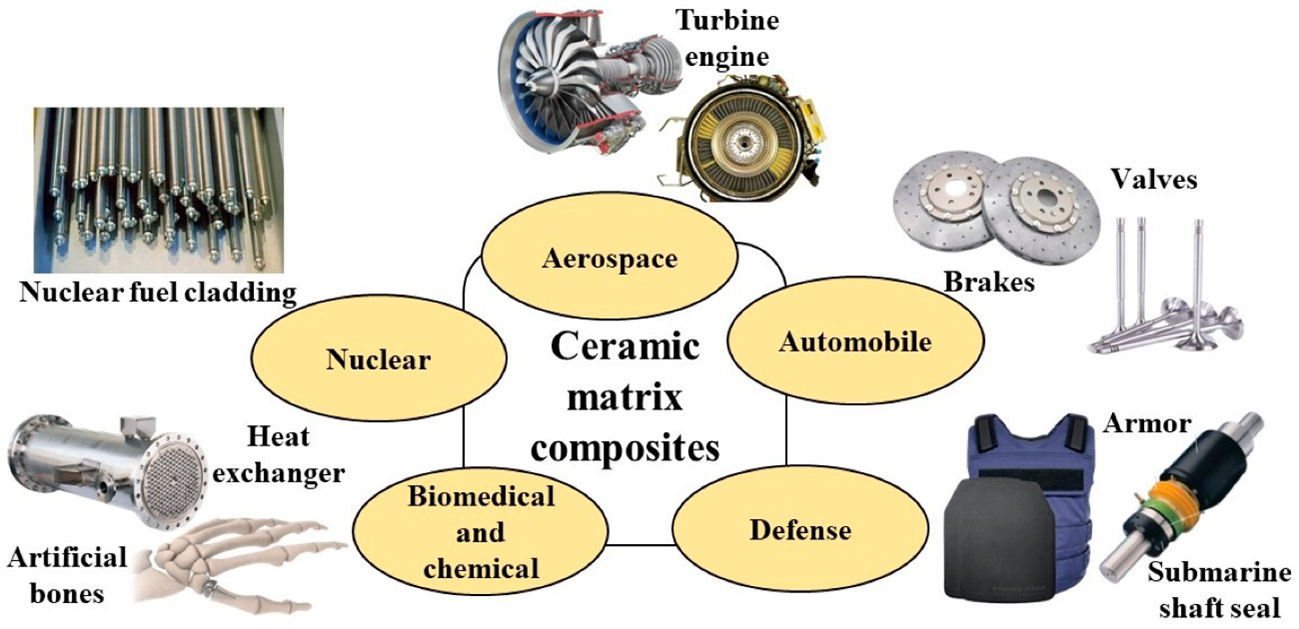

Ceramic Matrix Composites (CMCs):

CMCs are known for their high-temperature stability, hardness, and resistance to wear and corrosion, making them suitable for use in turbine engines, brake discs, and space vehicle components.

Source : mdpi.com

-

Natural Fiber Composites:

Made from renewable resources like hemp, flax, or jute, these are gaining popularity for sustainable engineering solutions. Their biodegradability and low cost make them attractive for green construction and low-load-bearing applications.

Source: sciencedirect.com

Mechanical Behavior

The mechanical behavior of composite materials is defined by various parameters:

- Tensile Strength: The maximum stress a composite can withstand while being stretched or pulled. It varies depending on the fiber type and matrix bonding.

- Compressive Strength: The capacity to withstand loads tending to reduce size. Proper fiber alignment and matrix support are crucial for optimal performance.

- Shear Strength: Resistance to forces that cause the internal structure to slide against itself. Critical in layered or laminated composites.

- Elastic Modulus: The ratio of stress to strain, indicating stiffness. A higher modulus indicates a stiffer composite.

- Fatigue Behavior: The durability of a material under repeated loading and unloading cycles. Composites often outperform metals due to their ability to arrest crack propagation.

- Fracture Toughness: The ability to resist crack propagation. Hybrid composites may be used to improve this property through synergistic effects.

Factors Influencing Mechanical Behavior of Composite Materials

- Fiber Orientation and Distribution: Uniform and aligned fibers significantly enhance strength and stiffness. Random fiber orientation, while easier to manufacture, often results in isotropic but lower mechanical properties.

- Matrix Material Properties: The matrix binds the fibers and transfers loads; its characteristics, such as ductility and thermal stability, affect the composite’s overall behavior.

- Volume Fraction of Reinforcement: Higher fiber content generally improves mechanical properties, though excessive fiber content can hinder matrix distribution.

- Interface Bonding: Strong bonding between matrix and fibers is critical for effective stress transfer. Surface treatments and coupling agents are often used to enhance bonding.

- Environmental Conditions: Exposure to moisture, temperature variations, and UV radiation can degrade mechanical properties over time. This necessitates proper material selection and protective coatings in outdoor or marine environments.

Testing and Evaluation Methods for Mechanical Behavior of Composite Materials

Mechanical testing of composites ensures quality and reliability:

- Tensile Testing: Measures how a material reacts to forces that attempt to pull it apart. Test specimens are prepared according to ASTM D3039 standards.

- Flexural Testing: Assesses a material’s ability to resist deformation under load. ASTM D790 is a common standard.

- Impact Testing: Determines toughness and resistance to sudden forces, often using Charpy or Izod methods.

- Fatigue Testing: Evaluates how materials withstand cyclic loading. S-N curves are generated to predict life cycles under varying stress levels.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing, thermography, acoustic emission, and X-ray inspection identify internal flaws, delaminations, or voids without damaging the material.

- Source: mdpi.com

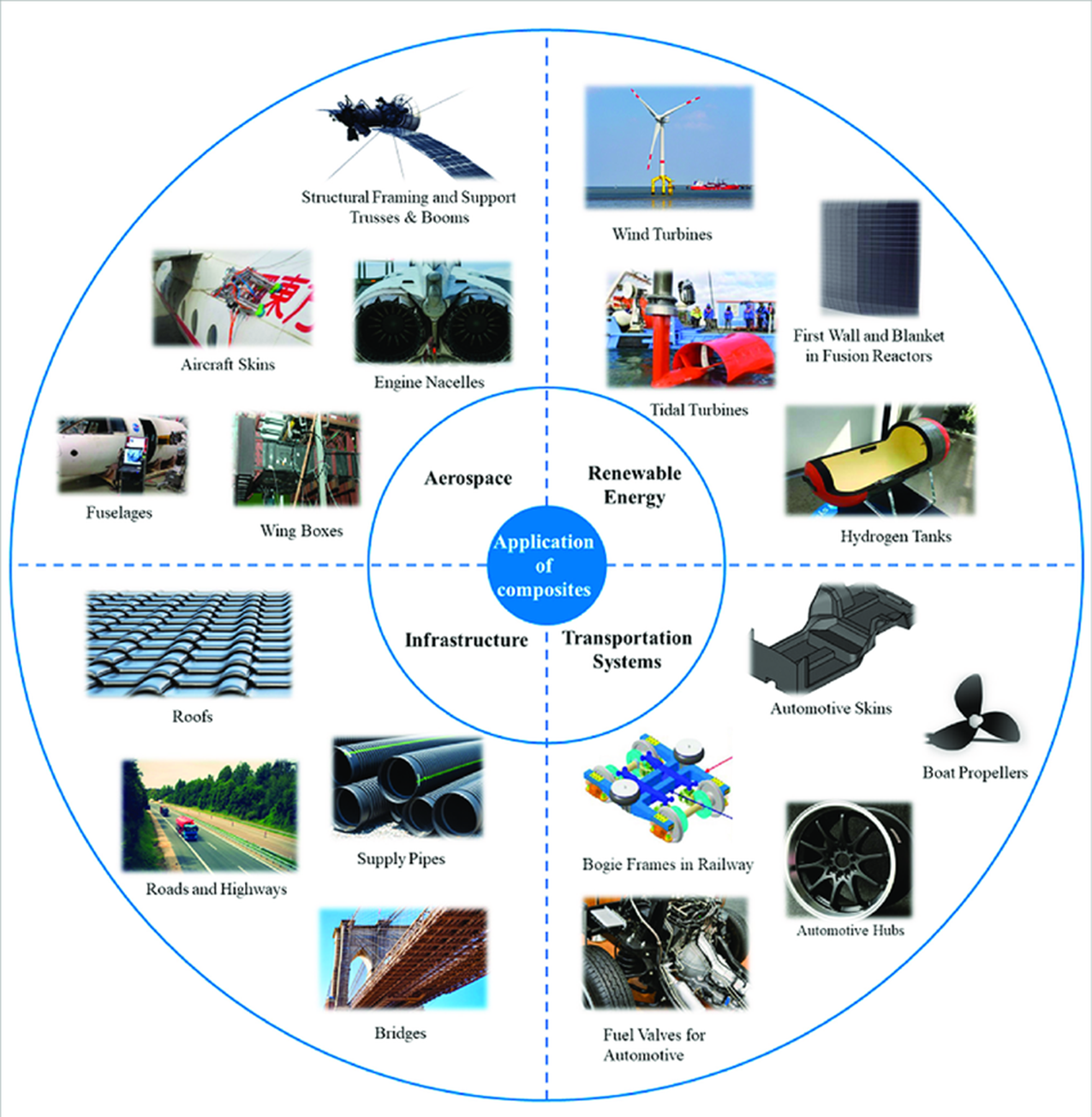

Applications in Mechanical Engineering

- Aerospace: Lightweight and strong composites reduce fuel consumption and enhance performance. Carbon fiber composites are widely used in fuselage, wings, and propellers.

- Automotive: Used for structural and aesthetic components to improve fuel efficiency and crash safety. Electric vehicle manufacturers use composites to offset battery weight.

- Civil Engineering: Reinforced concrete structures, bridge components, and retrofitting materials benefit from composites. Fiber-reinforced polymer (FRP) bars and wraps are used for strengthening aging infrastructure.

Source: researchgate.net

- Marine: Resistance to corrosion makes composites ideal for boat hulls, masts, and underwater structures. Glass fiber composites dominate this sector due to cost-effectiveness.

- Sports Equipment: High-performance sports gear, such as bicycles, tennis rackets, and golf clubs, leverage composites for strength, vibration damping, and reduced weight.

Challenges and Future Trends

Despite their advantages, composite materials face challenges:

- Manufacturing Complexity: Requires specialized processes such as autoclaving, pultrusion, or resin transfer molding (RTM), along with strict quality control.

- Cost: High material and processing costs can be a barrier to adoption, especially in cost-sensitive markets.

- Recycling: Difficulty in recycling composite materials due to their heterogeneous nature. Thermoplastic composites and reversible bonding agents are being researched to address this issue.

Future trends

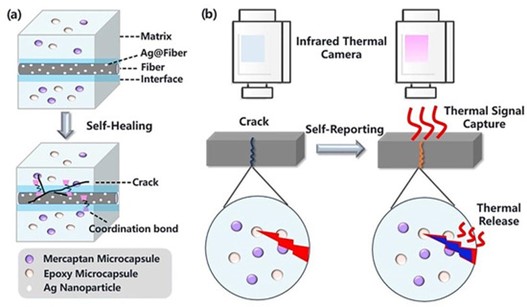

The development of self-healing composites that can autonomously repair microcracks, smart materials with embedded sensors for real-time structural health monitoring, and more sustainable, bio-based composites derived from plant oils or agricultural waste. Additive manufacturing (3D printing) is also being explored for customized and efficient composite part fabrication.

Conclusion

By offering superior strength, stiffness, and durability, composites continue to replace traditional materials in demanding applications. Ongoing research and technological advancements promise to overcome current limitations, paving the way for broader usage and innovation in composite engineering.

Magnify Your Mechanical Engineering Potential at KEN Institute!

Join Ken Institute and explore flexible online courses designed for working professionals. Elevate your career and gain a global edge with learners from 63+ countries!

Connect now and take the next step toward professional excellence!

Get in touch with us at: info@keninstitute.com

Visit our website: www.keninstitute.com

Call us on +917569034271

Let’s connect together on: Facebook, YouTube, LinkedIn, and Instagram.