Safety Toolbox Talks are a way to ensure all workers are participating in safety activities and have an opportunity to discuss hazards/controls, incidents, and accidents. It is an efficient hands-on way to remind workers that health and safety are important on the job. Through Safety Toolbox Talks you can tell workers about health and safety requirements for the tools, equipment, materials, and procedures they use every day or for particular jobs.

Who Can Give Toolbox Talks?

A person having good knowledge of that particular project can conduct the discussion. A supervisor, team leader, project manager or any person with experience in the topic can give the talk.

Not everybody has the personality to be a trainer.

These individuals don’t necessarily have any training or skills in training other people.

How Often Should Safety Toolbox Talks Be Done?

A 5-minute safety talk each day before work begins, is the best option to remind workers of workplace safety, they reinforce the idea that all are responsible for the whole crew.

How to Use the Safety Toolbox Talks?

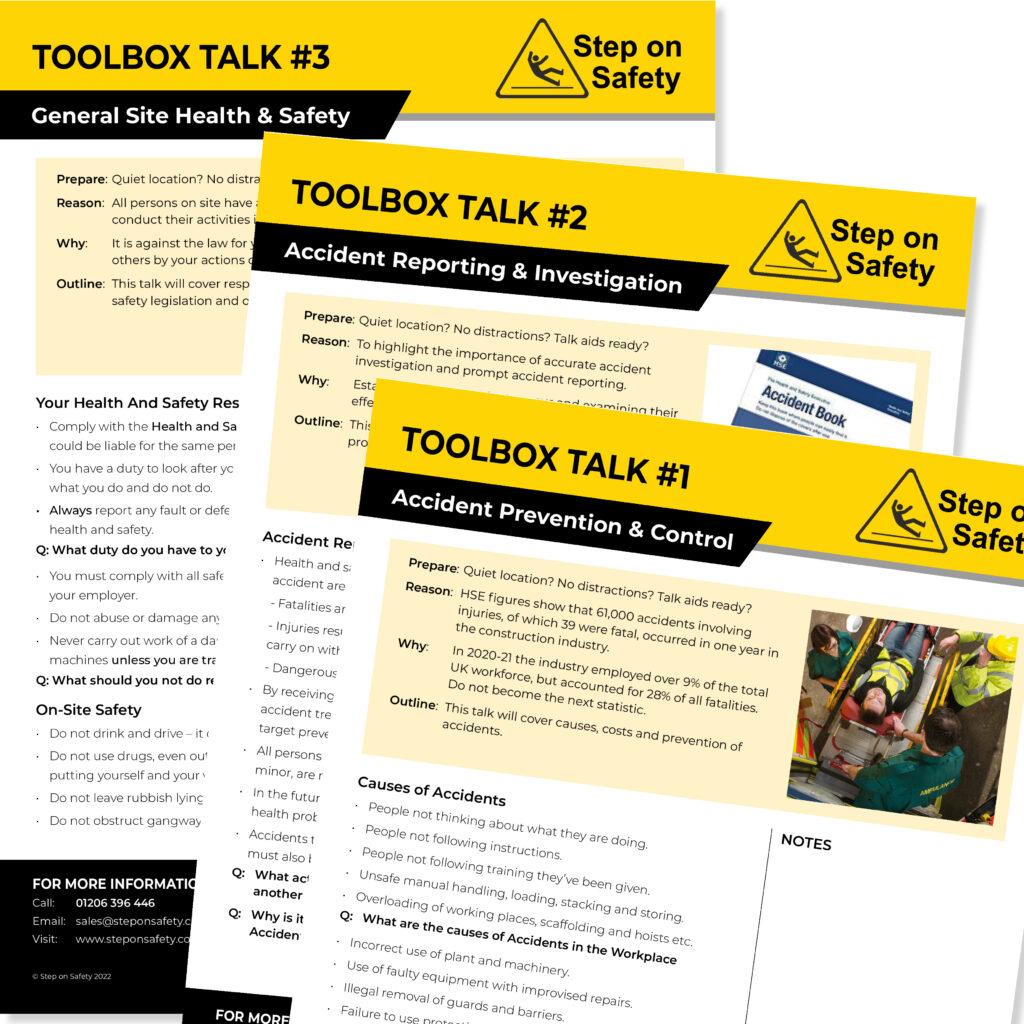

The Safety Toolbox Talks can be used one at a time for short safety or can be used as modules in a longer training session, such as annual refresher training. No training expertise is needed by the presenter to run sessions with the guidance of The Toolbox Talks material.

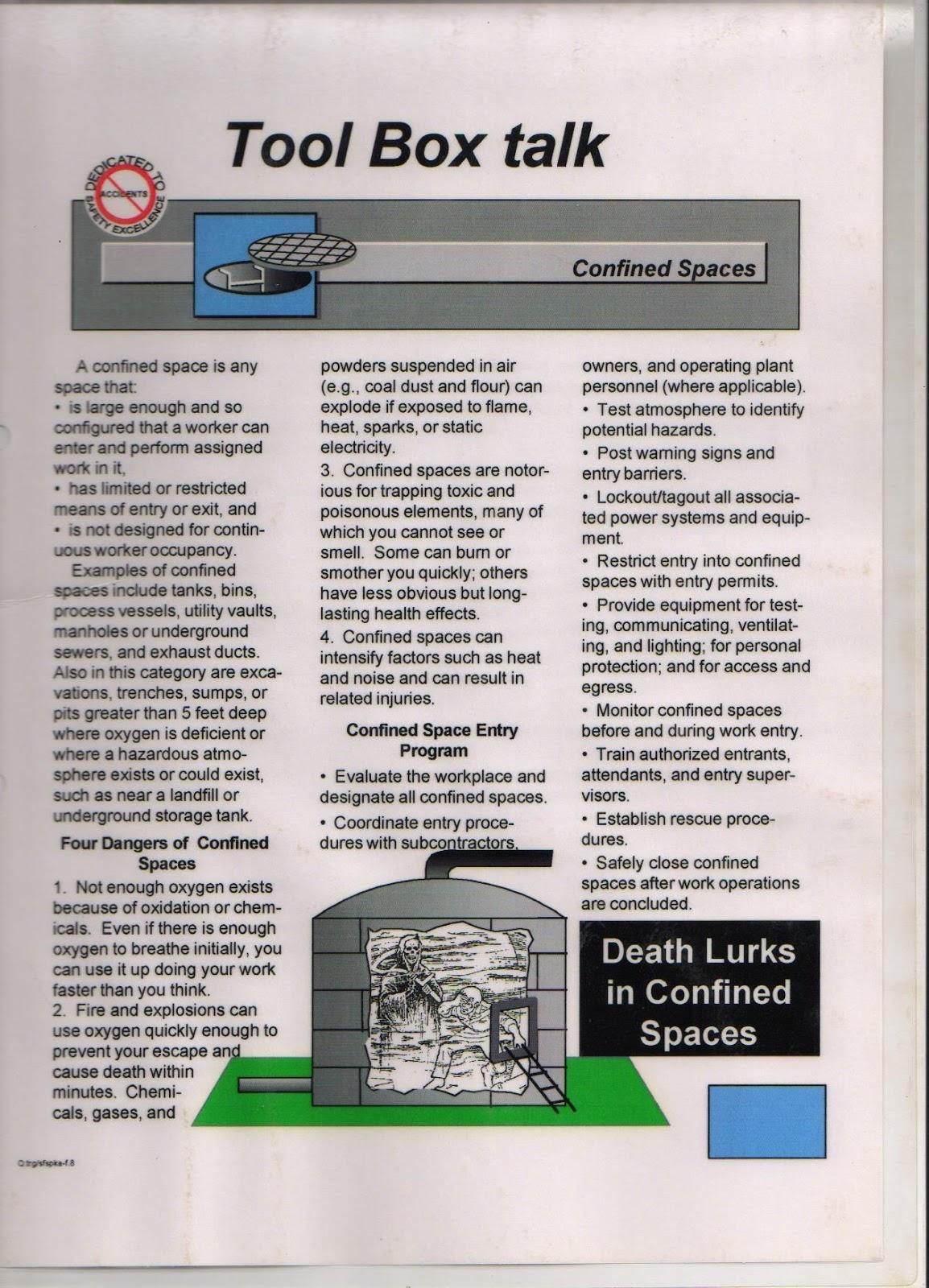

The materials provide support for brief presentations and discussions about a series of safety and health hazards. Each topic includes several questions that can be used to guide brief discussions.

During the discussions, workers are encouraged to relate the hazard covered to their own work environments.

Each Toolbox Talk Should Contain Following Sections:

- What we heard about hazard or risk

During interviews with workers, researchers wrote down what workers identified as critical hazards and risks. The thoughts and stories presented in the talks were taken from those notes.

- Is it really a risk?

The hazard or risk is explored by analyzing data from the accident and injury database consistent with the realities of accidents, injuries, and fatalities.

- It really happens!

A specific fatality, injury, or near miss is presented as an example to highlight an actual event that took place at a mine site. In order to provide the most appropriate example.

- Think about it.

Each talk ends with questions that help those participating ties the hazard or risk information to their worksite. The person conducting the talk can use these questions to start a discussion that will make the information relevant to participating employees.

Guidelines to Conduct Safety Toolbox Talk

- Choose a talk suited to site and work conditions.

- Deliver the talk where it will be most appropriate such as job office, out on the site, or near the tools and equipment you are talking about.

- Introduce the subject clearly.

- Let workers know exactly what you are going to talk about and why it’s important to them.

- Refer to the Safety Talk for information. But wherever possible use your own words.

- Connect key points to things your crew is familiar with on the project.

- Talk about what may happen.

- Explain how to control or prevent these hazards.

- Use real tools, equipment, material, and jobsite situations to demonstrate key points wherever possible.

- Ask for questions. Answer to the best of your knowledge.

- Ask workers to demonstrate what they have learned.

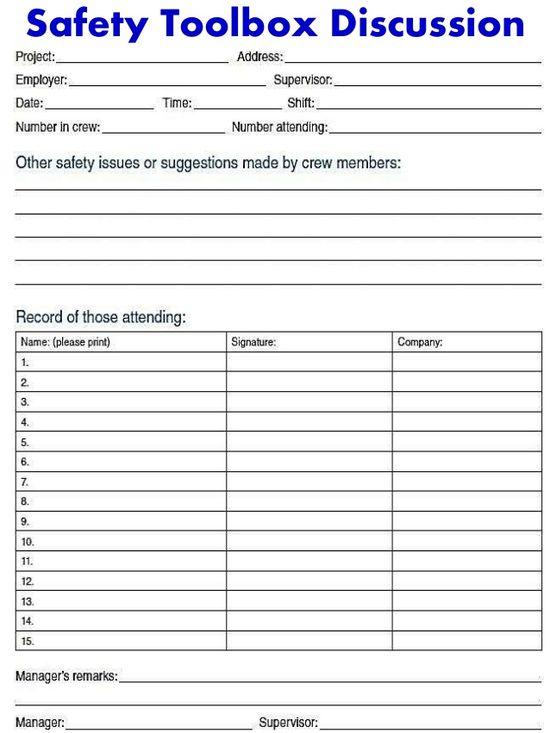

Don’t forget to: Keep a record of each talk delivered. Include date, topic, and names of attendees. Photocopy the Report Form at the back of this manual and use it to keep a record of each session.

How to Give an Effective Toolbox Talk

Here are some tips to learn your workforce some vital information.

Be Relevant

There is definitely something to be said for broadening one’s horizons, or getting an awareness of a topic so that your employees can spot hazards others might be encountering.

Look for topics that apply to your crew. Observe them in the field to see which subjects seem to be in need of refreshing. When your employees can personally relate to what is being discussed, it is much more likely to leave a lasting impression.

Be Engaging

This is what a Toolbox Talk sounds like too many employees: “Today we are going to talk about –blah blah blah blah.” It doesn’t take long for an employee’s personal concerns, family issues, or plans to creep into their minds.

One way to prevent this is to use visuals, Visuals encourage interaction. They use two of the employees’ senses (hearing and vision), rather than one. It’s a lot easier for us to tune out something we’re hearing that it is to ignore something we’re seeing.

Don’t just talk. Show your people how to use a new tool or machine safely. Safety is a physical thing, which makes demonstrations relatively easy to come up with.

The tone of your voice is also important. You should sound interested in the topic. Narrate interesting stories to relate from your personal experience. Your enthusiasm will translate into employee enthusiasm. They should believe you are an authority on the subject.

Involve Personnel

Your employees may be tired of your voice listening week in and week out, even if you’re the best trainer around. Find ways to involve the employees, whether by having them deliver the toolbox talks themselves or by having them volunteer personal stories that relate to the topic.

Ask them questions as you go. You could quiz them afterwards keeping them involved and attentive.

If you’re observant, your employees’ body language and behaviour will tell you a great deal about what they do and do not know.

Manage the Meeting

Getting employees involved is important, but you also have to be careful to manage the meeting. You may be turning some of the content over to your personal, but you are still in charge of the meeting. It is important to keep it focused.

Allow discussion, but when it starts to veer off course, jump back in and point it where it needs to go. If you have a guest speaker, make sure they’re staying on track for the allotted.

Make the meeting fun, but keep it under control.

Safety Toolbox Talks are about enhancing employee safety, not just being present long enough to sign an attendance sheet.

One good toolbox talk could be the difference between life and death.

“Join Ken Institute for comprehensive Health and Safety courses led by expert faculty, ensuring your readiness to tackle workplace fire emergencies effectively.”

For More Queries write us at info@keninstitute.com

visit our website at www.keneducation.in

call us on +917569034271

Let’s connect together on Facebook, YouTube, LinkedIn, Instagram.