The Middle East region historically synonymous with fossil fuels, is undergoing a remarkable energy transformation, with solar power at its core. The Middle East’s energy sector is experiencing a significant Solar Energy Boom, driven by a confluence of factors including ambitious government targets, declining technology costs, and abundant solar resources. Mechanical Innovations play a pivotal role in this expansion, increasing efficiency, reducing balance-of-system costs, and improving reliability in harsh desert conditions.

Leading Trends: Advanced Technologies & Systems

Advanced Solar Tracking Systems

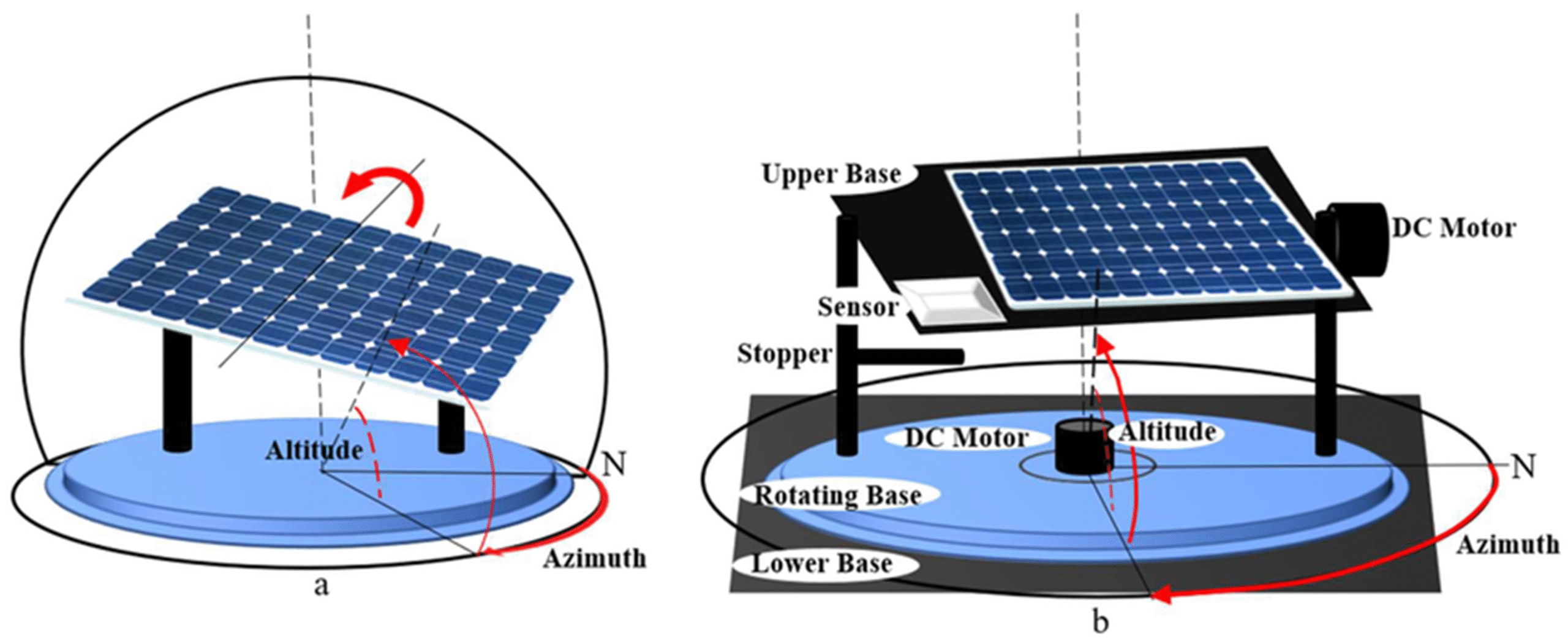

The simplest way to maximize energy output is to ensure solar panels are always directly facing the sun. Advanced mechanical tracking systems are crucial in the harsh desert environment.

Single-Axis Trackers: These are the workhorses of large-scale solar farms. This can increase energy production by 20-25% compared to fixed-tilt systems. These systems allow solar panels to follow the sun’s path from east to west throughout the day. This maximizes the amount of direct sunlight captured, significantly increasing energy output compared to fixed-tilt systems.

Innovation: Modern single-axis trackers are becoming more robust, capable of withstanding high winds common in desert environments, and feature improved drive mechanisms for smoother and more precise movement.

Dual-Axis Trackers: These boost the Middle East’s solar energy boom by tracking the sun’s daily east-west movement and its seasonal north-south altitude change. While more expensive and complex, they can yield up to a 35% gain in energy production, making them ideal for high-value applications. Dual-axis trackers follow the sun both horizontally and vertically, achieving the highest possible energy yield. They are increasingly being adopted for utility-scale projects where maximum output is crucial.

Innovation in Durability: Engineers are designing these systems with robust materials and sealed mechanisms to withstand the region’s major challenges: high winds, dust storms, and corrosive sand.

Lightweight, durable mounts: Aluminum or composite materials reduce weight, lowering structural loads and installation complexity.

Control algorithms: Real-time sun position and weather data optimize tracking angles, reducing wear and tear.

Robotic and Automated Cleaning Systems

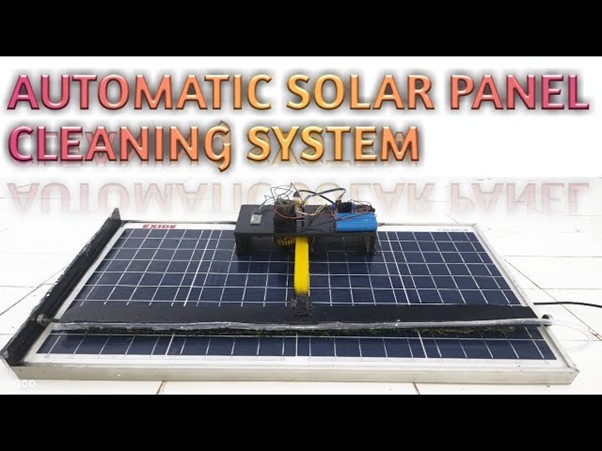

Dust and sand accumulation is the biggest operational challenge for Middle Eastern solar plants. A layer of dust can reduce panel efficiency by over 20% in a matter of weeks. Manual cleaning for thousands of panels is impractical and water-intensive.

Autonomous Robotic Cleaners: These are self-powered (often by their own small solar panels) robots that traverse the rows of panels, cleaning them with rotating brushes or microfiber cloths. They operate during the night or early morning without interrupting power generation.

Innovation: These robots are becoming more intelligent, using sensors to detect soiling levels and optimize cleaning schedules. Some systems also incorporate water-saving technologies or operate dry.

Water-Free and Water-Efficient Systems: Given the region’s water scarcity, innovations like air-blowing robots and electrostatic dust-removal systems are being deployed to minimize or eliminate water use.

Centralized Cleaning Systems: Some large plants use gantry systems essentially a giant moving bridge or crane structure that spans entire solar arrays, carrying cleaning apparatus back and forth.

Benefits:

Self-cleaning coatings: Hydrophobic or anti-soiling surfaces reduce cleaning frequency.

Robotic cleaning systems: Autonomous or semi-autonomous bots that minimize downtime and labor costs.

Water-efficient cleaning: Dry cleaning approaches and minimal-water sprays are increasingly common in water-scarce regions.

Improved Inverter and Power Conditioning Systems

Centralized vs. String Inverters: While advancements are ongoing for both, string inverters offer greater modularity and better performance in partially shaded conditions. Innovations focus on higher efficiency, improved thermal management for extreme temperatures, and enhanced grid integration capabilities.

Advanced Cooling Technologies: Inverters generate heat, and operating in high ambient temperatures requires sophisticated cooling solutions. Innovations include passive cooling designs and more efficient active cooling systems that can operate reliably in desert conditions.

Thermal Management and Cooling for PV Modules

Passive cooling plates and heat spreaders: Mitigate heat-induced efficiency losses in high-temperature climates.

Active cooling solutions: Water or air cooling for concentrated photovoltaic (CPV) and high-temperature PV systems in ultra-hot conditions.

Thermally conductive back sheets and phase-change materials: Improve heat dissipation and longevity.

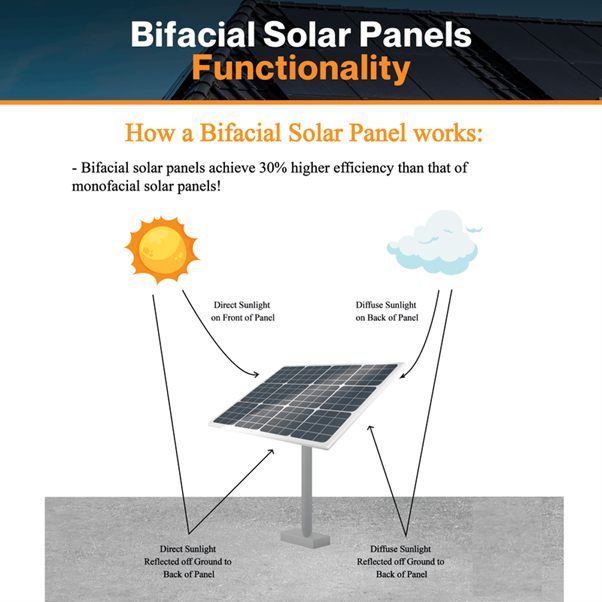

Bifacial Solar Panel Technology used to boom the Middle East’s solar energy

Enhanced Solar Panel Mounting Structures: This is a fundamental design innovation with a mechanical component. Bifacial panels capture sunlight from both sides. The front side captures direct sunlight, while the rear side captures albedo light sunlight reflected off the ground’s surface.

The Mechanical Advantage: To maximize this gain, the panels are mounted high enough off the ground and on tracking systems that allow reflected light to reach the rear side. The high albedo of the desert’s sandy, light-colored terrain makes this technology particularly effective in the Middle East, providing a 5-20% energy boost.

Robust Structural and Material Innovations

Durable and Lightweight Materials: Traditional steel structures are being supplemented or replaced by materials like aluminum alloys and advanced composites that offer better corrosion resistance (crucial in arid, salty environments) and reduced weight, simplifying installation and reducing transportation costs.

Modular and Pre-assembled Designs: Prefabricated mounting systems, fast assembly and scalability for large solar farm expansions reduce on-site assembly time and labor costs. This modularity also allows for quicker scaling of solar farms.

Wind Load Mitigation: Innovative structural designs and anchoring systems are developed to withstand extreme wind events, ensuring the longevity and safety of solar installations in the region. This includes aerodynamic panel tilts and robust foundation solutions.

Dust mitigation design: Sealed enclosures, splash guards, and vibration-minimized assemblies and protective coatings for saline desert air and dust to reduce maintenance.

Concentrated Solar Power (CSP)

A Mechanical Marvel: While photovoltaic (PV) panels convert sunlight directly to electricity, CSP uses mechanics and thermodynamics on a grand scale. It is uniquely suited for the region’s direct solar irradiance.

Solar Power Towers: Thousands of sun-tracking mirrors (heliostats) focus immense amounts of solar energy onto a central receiver atop a tower, heating molten salt to over 500°C. The molten salt acts as a thermal battery, allowing the plant to generate electricity 24/7, even after sunset. This mechanical energy storage is a key advantage over conventional batteries.

Solar Thermal ( CST ) Innovations

Tower and parabolic trough designs: Long, curved mirrors focus sunlight onto a receiver tube running along their focal line efficiently concentrate solar energy for steam turbines. A heat-transfer fluid inside the tube is heated to high temperatures (around 400°C) to produce steam and drive a turbine.

High-temperature thermal storage: Molten salt or other phase-change materials store heat for power generation after sunset.

Heliostat mechanics: Precision-aiming mirrors with robust drive systems for long-life operation in dusty environments.

Heat exchangers and receivers: Durable, corrosion-resistant materials tailored to desert conditions.

- Structural and Mounting Innovations

The physical installation of solar panels in a desert environment presents unique challenges.

Ballasted Ground-Mount Systems: Instead of drilling foundations into the hard, rocky desert ground, these systems use weighted concrete blocks to hold the solar array structure in place. This significantly reduces installation time, cost, and ground disturbance.

Corrosion-Resistant Materials: All mounting structures, bolts, and trackers are being manufactured from specially coated steels, aluminum, and composites to resist the corrosive effects of sand and high temperatures.

- Water Management and Cooling Solutions for CSP

Dry Cooling Technologies: While photovoltaic (PV) solar is dominant, Concentrated Solar Power (CSP) also plays a role. For CSP plants that use water for cooling, innovative dry cooling systems are crucial to reduce water consumption in an already water-scarce region.

Advanced Heat Transfer Fluids: Research into more efficient and stable heat transfer fluids for CSP systems aims to improve thermodynamic efficiency and operational reliability.

future.

- Storage-Integrated Mechanical Solutions

Mechanical integration with grid storage: Hybrid systems combining solar with thermal or battery storage, requiring robust heat exchange and thermal management.

Pumped-storage or compressed-air concepts: In some regions, mechanical storage innovations complement solar generation.

- Maintenance and Asset-Management Robotics

Robotic inspection crawlers: Ultrasound, thermal imaging, and dust control for early fault detection.

Drones for thermal imaging and surveys: Rapid, wide-area fault detection and performance monitoring. Drones equipped with thermal and visual cameras can quickly inspect large solar farms for panel defects, hot spots, or structural damage, reducing the need for manual inspections and minimizing downtime.

Impact of These Innovations

These mechanical innovations contribute to the Middle East’s solar energy boom in several ways:

- Increased Energy Yield

- Reduced Levelized Cost of Energy (LCOE)

- Enhanced Reliability and Durability

- Faster Deployment

- Water Conservation

Challenges and Considerations

Dust and sand ingress can wear mechanical components; ongoing sealing and filtration are crucial.

Maintenance in remote desert locations demands remote diagnostics, modular spare parts, and local service ecosystems.

Supply chain volatility for specialized materials requires local manufacturing and standardization.

Water use remains a constraint; innovations favor dry cleaning and dry cooling where possible.

Summary

The Middle East’s solar energy boom is a powerful demonstration of how mechanical engineering is solving region-specific problems. By innovating in tracking, cleaning, structural design, and thermal storage, engineers are turning the region’s most abundant resource sunlight into a reliable, cost-effective, and dominant source of energy, paving the way for a post-oil future and unlocking the full potential of the Middle East’s vast solar resources, solidifying its position as a global leader in solar energy!

Join Us!

Join us and unlock a world of online courses in Mechanical Engineering, Occupational Health and Safety, Fire Safety, and Environment and Sustainability. Propel your career to new heights.

Connect now and take the next step toward professional excellence!

+91 7569034271

Let’s connect together on: Facebook, YouTube, LinkedIn, and Instagram.