Personal protective equipment or PPEs includes a variety of devices and garments: protective clothing, helmets, goggles, face shields, safety glasses, hard hats, safety shoes, coveralls, gloves, vests, earplugs, respirators, etc.

PPE is designed to protect workers from serious workplace injuries or illnesses resulting from workplace hazards such as contact with chemical, radiological, physical, electrical, mechanical, heat, biohazards, airborne particulate matter, and many other hazardous substances.

Protective garments or equipment designed to protect the wearer’s body from injury or infection. These may be worn for job-related occupational safety and health purposes, as well as for sports and other recreational activities.

The Purpose of Personal Protective Equipment

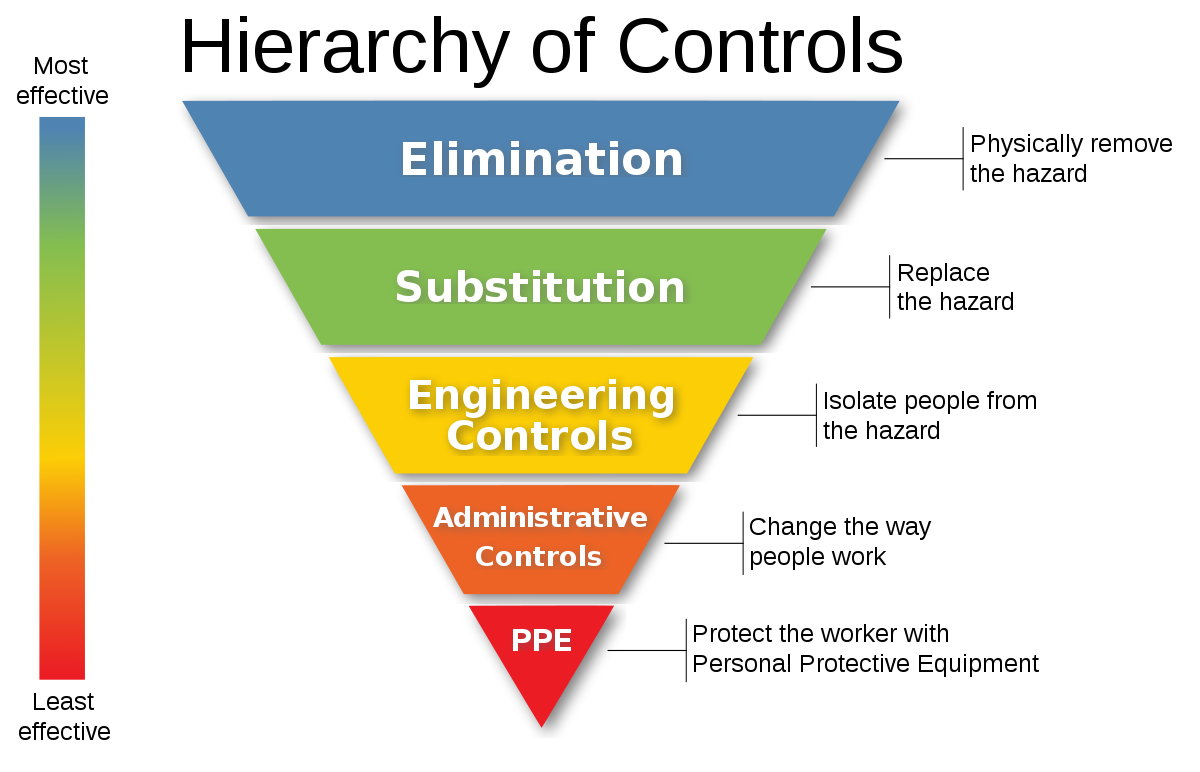

PPEs reduce employee exposure to hazards when engineering controls and administrative controls are not feasible or effective to reduce these risks to acceptable levels. PPE is needed when there are hazards present.

To mitigate workplace hazards, The Hierarchy of Hazard Controls provides a policy framework that ranks the types of hazard controls in terms of absolute risk reduction. At the top of the hierarchy are elimination and substitution, which replace the hazard with a safer alternative. Personal protective equipment ranks last on the hierarchy of controls, as the workers are regularly exposed to the hazard, with a barrier of protection.

The hierarchy of controls is important in acknowledging that, though at the lowest step, personal protective equipment has tremendous utility, in terms of worker safety.

Types of Personal Protective Equipment

PPEs can be categorized by:

- the area of the body protected

- the types of hazard

- the type of garment or accessory

The protective attributes of each piece of equipment must be compared with the hazards expected to be found in the workplace.

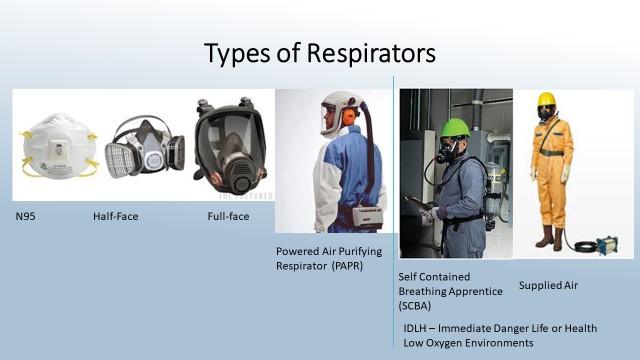

Respirators

Respirators serve to protect the user from breathing in contaminants in the air, thus preserving the health of their respiratory tract. In work environments, respirators are relied upon when adequate ventilation is not available or other engineering control systems are not feasible or inadequate.

There are two main types of respirators

- Functions by filtering out chemicals and gases, or airborne particles, from the air breathed by the user. The filtration may be either passive or active (powered). Gas masks and particulate respirators (N95 masks) are examples of this type of respirator.

- Protects users by providing clean, respirable air from another source. This type includes airline respirators and self-contained breathing apparatus (SCBA).

Surgical masks are considered as PPE but are not considered respirators, being unable to stop submicron particles from passing through, and also having unrestricted airflow at the edges of the masks.

Skin Protection

Occupational skin diseases such as contact dermatitis, skin cancers, and other skin injuries and infections are the second-most common type of occupational disease and can be very costly. Any form of PPE that acts as a barrier between the skin and the agent of exposure can be considered skin protection.

Skin hazards, which lead to occupational skin disease, can be classified into four groups:

- Chemical agents can come into contact with the skin through direct contact with contaminated surfaces, deposition of aerosols, immersion, or splashes.

- Physical agents such as extreme temperatures and ultraviolet or solar radiation can be damaging to the skin over prolonged exposure.

- Mechanical trauma occurs in the form of friction, pressure, abrasions, lacerations, and contusions.

- Biological agents such as parasites, microorganisms, plants, and animals can have varied effects when exposed to the skin.

Gloves: commonly used as PPE include rubber gloves, cut-resistant gloves, chainsaw gloves, and heat-resistant gloves. For sports and other recreational activities, many different gloves are used for protection, generally against mechanical trauma.

Lab coats: are worn to protect against potential splashes of chemicals.

Face shields: serve to protect one’s face from potential impact hazards, chemical splashes, or possible infectious fluid.

Protection from Foot and Leg Injuries

Boots: provide multiple forms of protection: a steel toe cap and steel insoles for protection of the feet from crushing or puncture injuries, impervious rubber and lining for protection from water and chemicals, high reflectivity and heat resistance for protection from radiant heat, and high electrical resistivity for protection from electric shock.

Foot guards and safety shoes, leggings: (e.g., leather, aluminized rayon, or other appropriate material) can help prevent injuries by protecting workers from hazards such as falling or rolling objects, and wet and slippery or hot surfaces.

Eye Protection

Eye injuries can happen through a variety of means. Most eye injuries occur when:

- Solid particles such as metal slivers, wood chips, sand, or cement chips get into the eye.

- Smaller particles in the smoke enter into the eye.

- Larger particles such as broken glass also account for particulate matter-causing eye injuries.

- Blunt force trauma can occur to the eye when excessive force comes into contact with the eye.

- Chemical burns, biological agents, and thermal agents, from sources such as welding torches and UV light, also contribute to occupational eye injury.

The required eye protection varies by occupation.

Safety glasses: provide protection from external debris, and should provide side protection via a wrap-around design or side shields.

Goggles: provide better protection than safety glasses, and are effective in preventing eye injury from chemical splashes, impact, dusty environments, and welding. Eye protection for welding is shaded to different degrees, depending on the specific operation.

Goggles with high air flow should be used to prevent fogging.

Face shields: are worn over the standard eyewear; they protect from impact, chemical, and blood-borne hazards.

Full-facepiece respirators: are considered the best form of eye protection when respiratory protection is needed as well.

Hearing Protection

Industrial noise is often overlooked as an occupational hazard, as it is not visible. Occupational hearing loss accounted for about 20% of all occupational illnesses, with cases to cause permanent hearing impairment, mostly in the manufacturing sector.

PPE for hearing protection consists of Earplugs and Earmuffs.

Workers who are regularly exposed to noise levels above the recommendation should be provided with hearing protection by the employers, as they are a low-cost intervention. The effectiveness of hearing protection varies with the training offered on their use.

Protective Clothing and Ensembles

This form of PPE is all-encompassing and refers to the various suits and uniforms worn to protect the user from harm. Lab coats worn by scientists and ballistic vests worn by law enforcement officials, which are worn on a regular basis, would fall into this category. Entire sets of PPE, worn together in a combined suit, are also in this category.

Ensembles

Ensembles of personal protective equipment, worn together for a specific occupation or task provide maximum protection for the user.

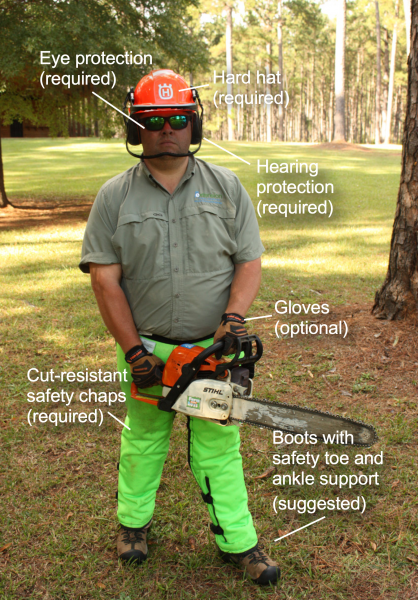

Chainsaw Protection

- Helmet with face guard

- hearing protection

- kevlar chaps

- anti-vibration gloves

- chainsaw safety boots

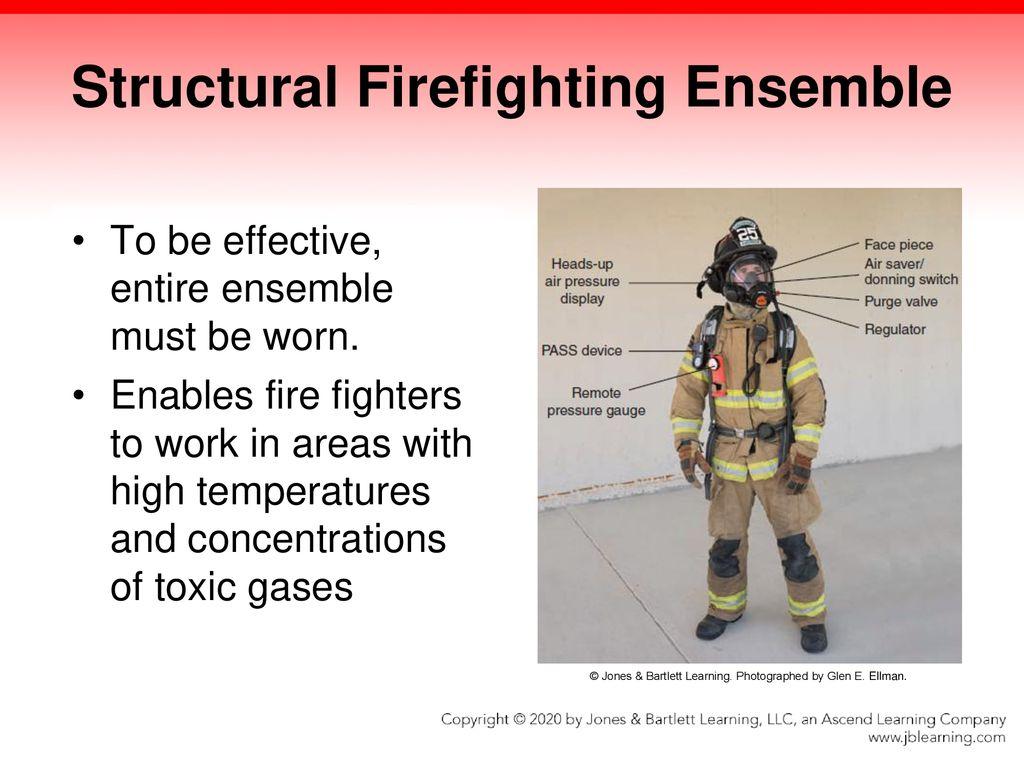

PPEs for Firefighters

Special types of PPE are designed to protect against fires and various fumes and gases. In addition to fire-retardant wool and fire-retardant cotton, materials used in whole-body personal protective equipment include rubber, leather, synthetics, and plastic.

Firefighter PPEs include:

- bunker gear

- self-contained breathing apparatus

- a helmet

- safety boots

- A PASS device.

OSHA’s Primary Personal Protective Equipment Standards

OSHA’s general personal protective equipment requirements mandate that:

- employers conduct a hazard assessment of their workplaces to determine what hazards are present that require the use of protective equipment

- Provide workers with appropriate protective equipment, and require them to use and maintain it in sanitary and reliable condition.

- Using personal protective equipment is often essential, but it is generally the last line of defense after engineering controls, work practices, and administrative controls.

- As an employer, you must assess your workplace to determine if hazards are present that require the use of personal protective equipment.

- If such hazards are present, you must select protective equipment and require workers to use it, communicate your protective equipment selection decisions to your workers, and select personal protective equipment that properly fits your workers.

- You must also train workers who are required to wear personal protective equipment on how to do the following:

- Use protective equipment properly

- Be aware of when personal protective equipment is necessary

- Know what kind of protective equipment is necessary

- Understand the limitations of personal protective equipment

- Put on, adjust, wear, and take off personal protective equipment,

- Maintain protective equipment properly.

- Also, OSHA regulations require employers to ensure that workers cover and protect long hair to prevent it from getting caught in machine parts such as belts and chains.

Limitations of Personal Protective Equipment

- PPE has the serious limitation that it does not eliminate the hazard at the source and may result in employees being exposed to the hazard if the equipment fails.

- Any item of PPE imposes a barrier between the wearer/user and the working environment. This can create additional strains on the wearer, impair their ability to carry out their work, and create significant levels of discomfort.

- Any of these can discourage wearers from using PPE correctly, therefore placing them at risk of injury, ill health, or, under extreme circumstances, death.

Good ergonomic design can help to minimize these barriers and can therefore help to ensure safe and healthy working conditions through the correct use of PPE.

“Join Ken Institute for comprehensive Health and Safety Courses led by expert faculty, ensuring your readiness to tackle workplace fire emergencies effectively.”

Without the use of proper Personal Protective Equipment, our jobs could not be performed safely and healthily. That is why it is important to wear the correct PPE for every job task to reduce the risk of injuries and illnesses in the workplace.

To discuss more and expand your perception around the health and safety topic,

Get in touch with us at: info@keninstitute.com

Visit our website: www.keneducation.in

Call us on +917569034271

Let’s connect on Facebook, YouTube, LinkedIn, and Instagram.

Tag: Health & Safety Health & Safety Training