A “Risk Assessment” is one of the major components of a risk analysis. It a systematic process used to identify potential hazards and risks in a situation, then analyze what would happen should these hazards take place. As a decision-making tool, risk assessment aims to determine which measures should be implemented to eliminate or control those risks, as well as specify which of them should be prioritized according to their likelihood and impact on the business.

HSE distinguishes three general risk assessment types:

Large Scale Assessments

This refers to risk assessments performed for large scale complex hazard sites such as the nuclear, and oil and gas industry. This type of assessment requires the use of an advanced risk assessment technique called Quantitative Risk Assessment (QRA).

Required specific assessments

This refers to assessments that are required under specific legislation or regulations, such as the handling of hazardous substances (according to COSHH regulations, 1998) and manual handling (according to Manual Handling Operations Regulations, 1992).

General assessments

This type of assessment manages general workplace risks and is required under the management of legal health and safety administrations such as OSHA and HSE.

Who Is Responsible for Risk Assessments?

- Responsibility for conducting risk assessments typically lies with the employer or the person in control of the workplace. However, depending on the organization and its structure, this responsibility may be delegated to:

- Managers or Supervisors: In larger organizations, managers and supervisors often conduct risk assessments within their specific departments or teams.

- Health and Safety Officers: Dedicated professionals with expertise in identifying and mitigating risks may oversee or perform risk assessments.

- External Consultants: In cases where specialized knowledge is required or internal resources are insufficient, organizations may hire external consultants to conduct risk assessments.

- Employees: Employees may contribute to the process, especially if they have firsthand knowledge of the hazards involved in their tasks. However, the ultimate accountability remains with the employer.

- Owners of Small Businesses: For small businesses, the owner or operator is usually responsible for conducting and documenting risk assessments.

When Should Risk Assessments Be Done?

· Importance of Timely Risk Assessments

Regular and timely risk assessments are essential to: Protect employees and others from harm. Ensure compliance with health and safety regulations. Minimize costs associated with workplace incidents, including fines and compensation claims. Promote a safe and healthy work culture.

· Risk assessments should be performed under the following circumstances:

- Before Starting a New Activity or Project: To identify potential hazards associated with new tasks, equipment, or processes.

- After Identifying New Hazards: If a new risk becomes apparent (e.g., changes in equipment, materials, or work conditions).

- When There Are Changes in the Workplace: During renovations, expansions, or other alterations that could introduce new risks.

- Periodically or Regularly: Routine assessments ensure ongoing compliance and effectiveness of existing safety measures.

- After an Incident or Near Miss: If an accident or near miss occurs, a reassessment can help identify root causes and prevent recurrence.

- When Required by Law or Industry Standards: Some industries mandate risk assessments at specific intervals or for certain activities.

- During New Employee Induction or Task Assignments: Assess risks for new roles or responsibilities to ensure employees are adequately trained and informed.

- Following Changes in Legal or Regulatory Requirements: Updates in health and safety laws may necessitate a review and update of risk assessments.

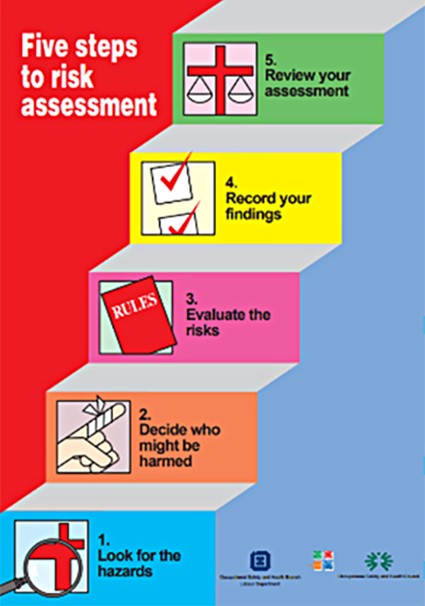

Steps for Conducting a Risk Assessment

Conducting a risk assessment involves a systematic approach to identifying, evaluating, and controlling risks in the workplace.

1. Identify Hazards

A hazard is anything that has the potential to cause harm (e.g., chemicals, equipment, work practices, or environmental conditions).

How to Identify Hazards:

· Conduct workplace walkthroughs.

· Review job tasks and processes.

· Analyze past incident reports or near misses.

· Consult with employees and safety representatives.

· Refer to safety guidelines, legal requirements, and industry standards.

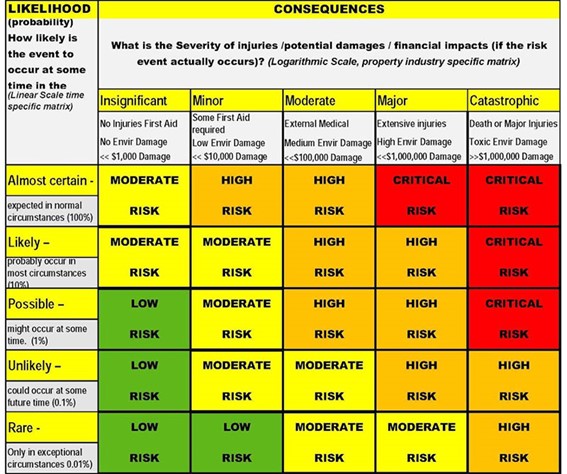

2. Use of Risk Matrix

A risk matrix is often used to measure the level of risk by considering the consequence/ severity and likelihood of injury to a worker after being exposed to a hazard.

Two key questions to ask when using a risk matrix should be: 1. Assess consequence? 2. Assess Likelihood?

Consequences: How bad would the most severe injury be if exposed to the hazard?

- Fatality– leads to death

- Major or serious injury– serious damage to health which may be irreversible, requiring medical attention and ongoing treatment

- Minor injury– reversible health damage which may require medical attention but limited ongoing treatment). This is less likely to involve significant time off work.

- Negligible injuries– first aid only with little or no lost time.

Likelihood: How likely is the person to be injured if exposed to the hazard?

It is common to group the likelihood of a hazard causing worker injury into the following four categories:

- Very likely– exposed to hazard continuously.

- Likely– exposed to hazard occasionally.

- Unlikely– could happen but only rarely.

- Highly unlikely– could happen, but probably never will.

The most common types are the 3×3 risk matrix, 4×4 risk matrix, and 5×5 risk matrix.

3. Evaluate Risks and Decide on Precautions

Risk is the likelihood of harm occurring combined with the severity of potential consequences.

Risk Evaluation: Assess Potential Harm: Think about specific injuries, illnesses, or long-term effects that could result from each hazard. Use qualitative or quantitative methods (e.g., risk matrices or scoring systems).

Control Measures: Apply the hierarchy of controls:

Elimination: Remove the hazard entirely.

Substitution: Replace the hazard with something less dangerous.

Engineering Controls: Use physical safeguards (e.g., barriers, ventilation systems).

Administrative Controls: Implement policies, procedures, and training.

Personal Protective Equipment (PPE): Use as a last resort for protection.

4. Record Findings and Implement Controls

Documentation: Record the hazards identified, who may be affected, the risks assessed, and the controls implemented.

Ensure records are clear, comprehensive, and accessible.

Implementation: Put the controls in place, assign responsibilities, and set deadlines for completion.

Communicate findings and actions to employees and relevant stakeholders.

5. Monitor and Review the Assessment

Continuous Monitoring: Ensure controls are effective and hazards remain under control.

Regular Reviews: Update risk assessments periodically or after significant changes (e.g., new processes, incidents, or regulatory updates).

Involve Employees: Encourage feedback and suggestions for improvements.

Best Practices for Conducting Risk Assessments

Engage Employees: Workers often have valuable insights into workplace hazards.

Be Specific: Tailor assessments to the specific tasks and environment.

Stay Up-to-Date: Keep abreast of changes in technology, processes, and regulations.

Focus on Practicality: Implement realistic and cost-effective controls.

Follow Legal Requirements: Ensure compliance with occupational health and safety laws.

Adapt Risk Assessment Template:

Tips for Using a Template

Customize for Your Workplace: Adapt the template to suit specific activities and work environments.

Simplify Risk Levels: Use a scale (e.g., 1-5) or labels (low/medium/high) to rate risks.

Keep It Focused: Avoid overcomplicating; focus on key hazards and controls.

Review Regularly: Ensure templates are updated to reflect new conditions or activities.

Risk Assessment Template

| Step | Description |

| Activity/Task | Describe the task or area being assessed. |

| Hazard | Identify potential hazards associated with the task. |

| Who Might Be Harmed | List individuals or groups at risk. |

| Risk Level | Assess the likelihood and severity (e.g., high/medium/low). |

| Existing Controls | Detail current measures to mitigate the hazard. |

| Further Actions Needed | Specify additional measures if current controls are insufficient. |

| Responsible Person | Name the person(s) responsible for implementing actions. |

| Completion Date | Set a timeline for implementing further actions. |

Summary

Promote a culture of accountability and transparency within your organization where every member takes ownership of their actions. Align governance practices, enhance risk management protocols, and ensure compliance with legal requirements and internal policies by streamlining and standardizing workflows through a unified platform.

We strive to prioritize preventative measures over-reactive solutions. We believe in equipping our readers with the knowledge and tools to maintain a safe and healthy work environment, which can prevent accidents or health issues from occurring in the first place.

“Safety has to be everyone’s responsibility… everyone needs to know that they are empowered to speak up if there’s an issue.”

Join Ken Institute and unlock a world of online courses in Occupational Health and Safety, Fire Safety, Environment and Sustainability and Mechanical Engineering, Propel your career to new heights.

Join Ken Institute and unlock a world of online courses in Occupational Health and Safety, Fire Safety, and Environment and Sustainability and Mechanical Engineering. Propel your career to new heights.

Get in touch with us at: info@keninstitute.com

Visit our website: www.keninstitute.com

Call us on +917569034271

Let’s connect together on: Facebook, YouTube, LinkedIn, and Instagram.